Mechanical Moduli of Viscoelastic Materials

A number of polymeric materials show properties in-between those of liquids and classical solids. These materials appear to be solid but under stress they show some continuous liquid-like deformation, that is, the deformation, even at low stress, is not reversible as it is the case for normal solids. The materials are often termed viscoelastic solids. In some other cases a polymer behaves more like a liqiud, that is, they can be indefinitley deformed but show some recovery of shape after the stress has been released. These materials are called elasticoviscous fluids.

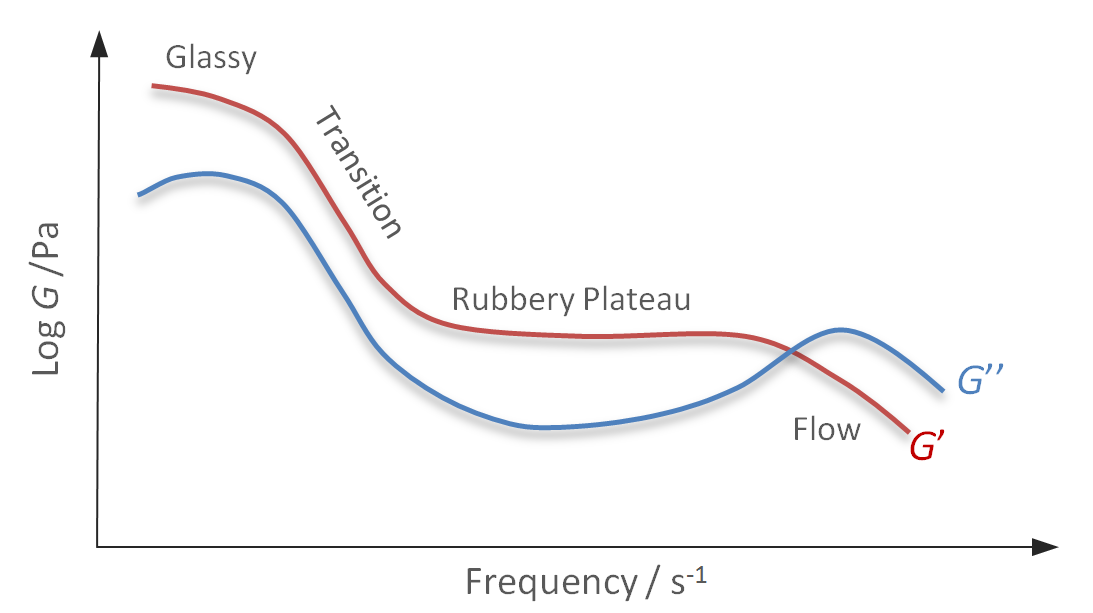

The energy of plastic deformation of a polymeric material can be related to the dynamic loss modulus (E'', G'') and the elastic deformation to the dynamic storage modulus (E', G') measured at different frequencies. The method that provides these properties is the Dynamical Mechanical Analysis or short DMA.

Both moduli, G' and G'', are of great importance to scientist and engineers since they can be correlated to basic polymer properties such as glass transition temperature (Tg) entanglement weight (Me), degree of crystallinity, crosslink density (νe), and many other properties. For example, the glass transition temperature is the temperature where the storage and loss modulus changes rapidly. It is often measured as the peak of the tan δ curve of the phase angle, called damping, which is equal to the ratio of the loss modulus to the storage modulus, tan δ = G'' / G'.

Modulus vs. Frequency

The entanglement weight, Me, can be

calculated from the modulus in the plateau region, that is, the

storage modulus in this region is proportional to the number

of chemical and physical crosslinks per unit volume, νe,

or

to the number of knots and branching points per unit volume in the polymer

network:1

G'p ≅ ρ R T / Me = νe R T

where G'p is the shear storage modulus of the plateau region, ρ the polymer density, R the gas constant and T the temperature.

The mechanical properties can be manipulated by changing the molecular weight (MW) and molecular weight distribution, molecular structure, crosslink density, and polymer composition. Understanding the effect of these parameters on the mechanical properties is key for successfully tailoring the viscoelastic properties of polymeric materials, like melt rheological, solid mechanical and adhesive properties.

The addition of a low molecular weight - low Tg compounds such as (compatible) plasticizers or oil will soften the polymeric materials, that is, both the loss and storage modulus will drop. Similarly, lowering the (average) molecular weight will result in softer polymers with lower Tg. However, the effect of the molecular weight (MW) on the two moduli is not the same as that of a plasticizer, that is, the effect of the MW on the storage modulus is usually stronger than on the loss modulus.

Increasing the crosslink density, νe, for example by vulcanizing or curing a polymeric material, will lead to a (significant) increase of the storage modulus but only to a (minor) increase of the loss modulus, and at higher crosslink densities even to a decrease of the loss modulus. A higher crosslink density will also raise the rubbery plateau.

Adding a compatible resin of a high(er) Tg but low(er) molecular weight will result in a stiffer product. As a consequence, the peak of the loss modulus, G'', will move to a lower frequency. This, in turn, will result in a lower loss modulus, G''. The effect on the storage modulus, G', is the opposit; at low frequencies, the storage modulus will increase due to the incresase in Tg. However, above the Tg, the plateau modulus will decrease, because adding a compatible low MW resin can be regarded as diluting a concentrated polymer solution with a solvent. The effect is proportional to the square of the volume fraction of the polymer in the blend:

G'p ≅ φp2 ρ R T / Me

where φp is the volume fraction of the polymer in the polymer-resin blend.

Another important parameter affecting the mechanical properties is the entanglement weight of the polymer(s), Me. With increasing Me, both the loss and storage modulus decrease, so does the glass transition temperature, Tg. The Me is closely related to the molecular structure of the polymer; for example, bulky side-groups increase steric hindrance and decrease chain mobility, which, in turn, increases the entanglement weight. The same is true for increased steric hindrance in the backbone.

Crystallinity has a similar effect on the mechanical properties as crosslinking. The crystalline domains act as physical crosslinks or reinforcements of the amorphous phase which increase the storage modulus and raise the rubbery plateau whereas both the loss modulus and tan δ decrease.