Polyoxadiazole Fibers

Properties

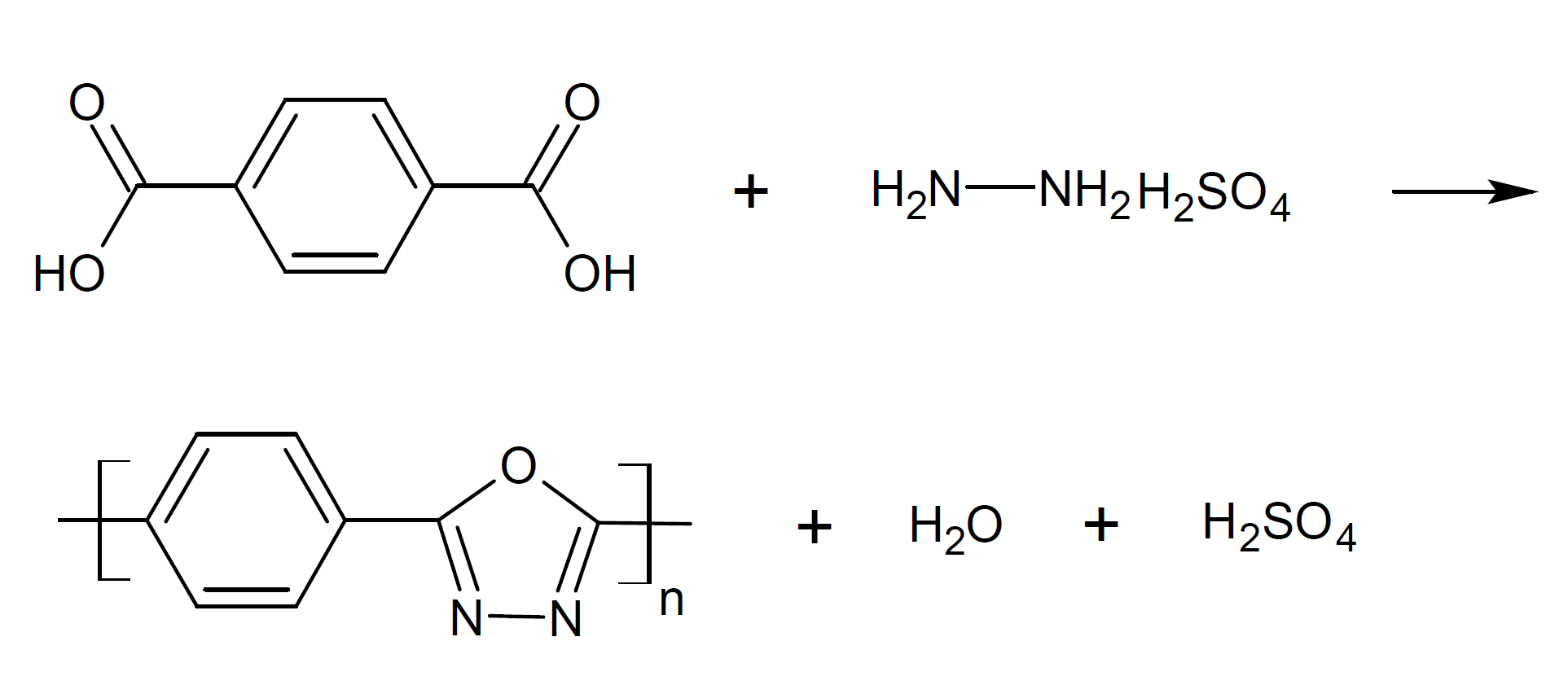

Polyoxadiazoles (POD) are a class of extremely strong, heat and chemical resistant synthetic thermoplastics. The only commercially important polyoxadiazole is poly(p-phenylene-1,3,4-oxadiazole) which can be synthesized by polycondensation of terephthalic acid and hydrazine sulfate at temperatures between 90 and 130°С.1

POD fibers, also known as Arselon, can be produced via solution spinning, using a solution of the polymer in either the polymerization solvent or another solvent for the polymer.2 They are rather expensive and difficult to produce, but unlike many other high molecular weight polymer fibers have no melting point. The fibers can withstand exposure to extreme heat and flame and become carbonized in inert media at temperatures higher than 550°С .1 The formation of a carbon structure increases the fiber density, tensile strength, and elastic modulus.

POD fibers possess properties very similar to those of m-aramid fibers. For example, like polyaramid, they have high strength and excellent dimensional stability due to the high young's modulus (stiffness & low elongation at break). They also exibits outstanding abrasion resistance, very low shrinkage and excellent electrical insulation properties.

COMMERCIAL POD Fibers

The only manufacturer of heat resistant polyoxadiazole fibers is Khimvolokno Svetlogorsk which is located in the Republic of Belarus. The company markets this fiber under the registered trademark “Arselon”, which is sold as filament yarns, milled fibers, needle felts, and woven fabrics.

Applications

Arselon fibers are used for high performance textile products and as fiber reinforcements. Important applications include heat resistant garments like safety gloves and firerfighting uniforms; rubber and plastic reinforcements for hoses, tires and belts; heat and chemical resistant filters; friction pads, abrasion-resistant bearings and bushings, and various other civil engineering textile products.

The maximum service temperature of POD fibers is typically in the range 230 - 250°С, and their thermal decomposition temperature is in the range 460 - 480°С.3

1M.V. Kriskovets,V.A. Lysenko, Y.N. Sazanov , G.N. Gubanova, E.M. Kulikova, V.L. Ugolkov, V.K. Lavrent’ev, Russian Journal of Applied Chemistry, Vol. 91, 1, pp 23–30 (2018)

2US 2013/0210306 A1, Flame resistant spun staple yarns made from blends of fibers derived from sulfonated polyoxadiazole polymers

3Y.N. Sazanov, I.P. Dobrovol’skaya, V.A. Lysenkob, P.Y. Sal’nikova, D.S. Kosyakov, S.A. Pokryshkin, G.N. Fedorova, and E.M. Kulikova, Russian Journal of Applied Chemistry, Vol. 88, 8, pp 1304–1310 (2015)