Aramid Fibers

Properties

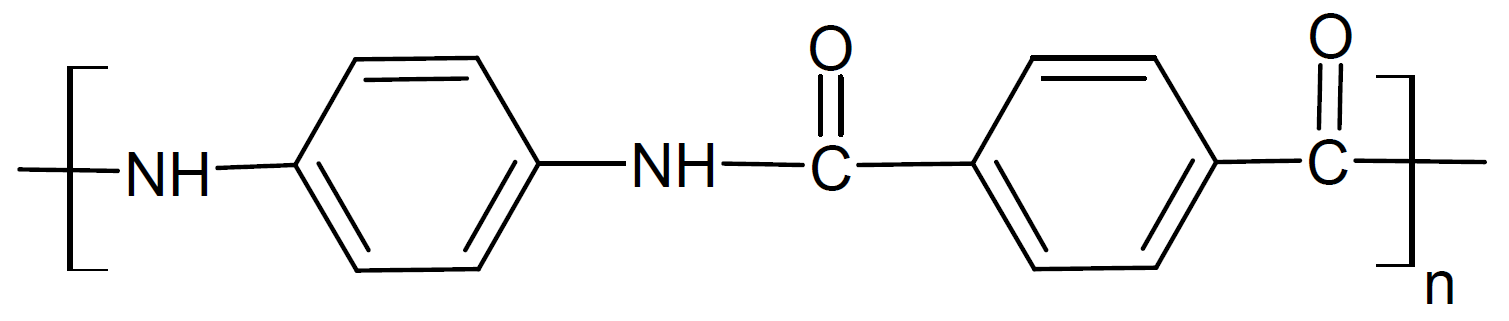

Aramid fibers are a class of extremely resilient and heat-resistant synthetic fibers. The fiber-forming substance is a long-chain synthetic polyamide in which at least 85% of the amide linkages are attached directly to two aromatic rings. The fiber is produced by spinning a solid fiber from a liquid chemical blend.

Aramid fibers are rather expensive and difficult to manufacture, but unlike high molecular weight polyolefin fibers, aramids have a polar aromatic polymer backbone, which results in a much higher glass transition temperature and no melting point. Due to the aromatic structure, aramid fibers have excellent heat resistance, very low flammability, and good chemical resistance to most organic solvents, but are sensitive to salt (chlorine), and to some acids and bases, as well as to degradation from ultraviolet radiation. Aramid fibers also have outstanding mechanical properties. This includes a high strength-to-weight ratio, even better than carbon, excellent dimensional stability due to the high young's modulus (stiffness & low elongation at break), and outstanding abrasion resistance and tenacity (difficult to cut or fray).

COMMERCIAL Aramid Fibers

Major manufacturers and suppliers of aramid fibers are DuPont, Toyobo, Aramid HPM, Fiberline, and Teijin. They are sold under the trademarks Kevlar, Nomex, Technora, and Conex.

Applications

Aramid fibers are used for very demanding applications. This includes ballistic-protective and stab resistant body armour like bulletproof vests; heat resistant garments like safety gloves and firerfighting uniforms; rubber and plastic reinforcements for hoses, tires and belts; high performance sporting goods; optical fibers; heat-resistant filters; and various other civil engineering textile products.