Polybenzimidazole

Properties

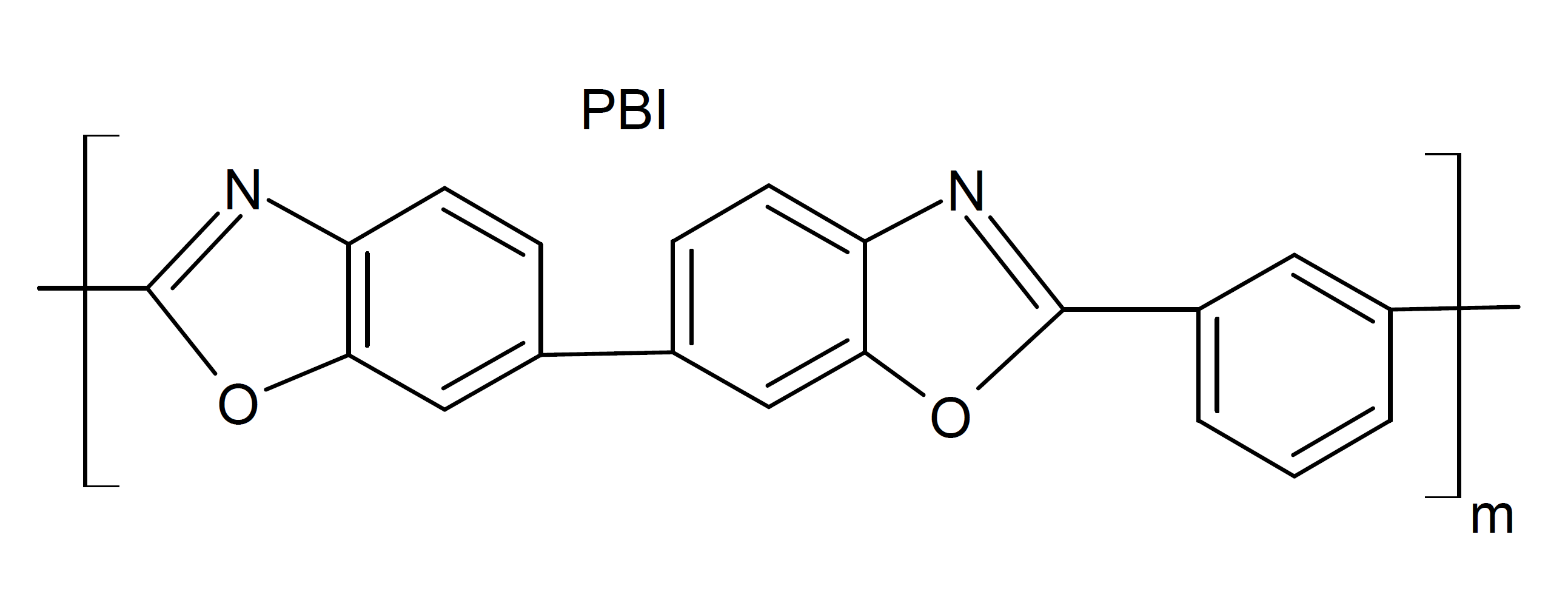

Polybenzimidazole fibers (PBI) are a class of extremely heat-resistant synthetic fibers. They are formed from completely aromatic polyamides. They are fibers in which the fiber-forming substance is a long-chain

aromatic polymer having recurring imidazole groups as one of the

main structural repeat units in the polymer backbone.

PBI is

prepared from an aromatic tetraamine and an aromatic dicarboxylic acid or a derivative

of it. The resin is then spun into fibers via a dry spinning process using dimethyl

acetamide as a solvent.

PBI fibers are rather expensive and difficult to manufacture, but have some of the best fiber properties. Due to the fully aromatic structure, PBI has a very high glass transition temperature (425°C / 800°F) and no melting point. Its heat deflection temperature at 264 psi (1.8 MPa) is about 815°F (435°C). The fiber also possesses outstanding heat stability and chemical resistance, including alcohols, hydrocarbons, chlorinated solvents, hydrogen sulfide, weak acids and bases, and many other chemicals. Its decomposition temperature is more than 1300°F (> 700°C)

PBI fibers are suitable for a wide range of high temperature applications. The fiber is flexible, has low tenacity, low moisture regain, does not burn or melt, and has an outstanding strength-to-weight ratio.

COMMERCIAL PBI Fibers

The only commercial PBI fiber is poly(2,2'-m-phenylene-5,5'-bibenzimidazole). Hoechst Celanese was the first to produce PBI articles under the trade name Celazole® (U-series) which was quickly followed by PBI-Polyaryleneketone blends (T-series). Today, the only producer of PBI fibers is PBI Performance Products1. The fiber and products made from it are also sold by Bally Ribbon Mills.

Applications

PBI fibers are an excellent choice for very demanding applications. They are often used for safety and heat resistant garments like safety gloves, and firefighter uniforms. PBI is also used as a plastic reinforcements, for heat and chemical resistant filters, and for various other civil engineering applications. The fiber is often blended with other high performance fibers like Kevlar®.

1The InterTech Group purchased the PBI business from Celanese in 2005.