Polyamideimide Fibers

Properties

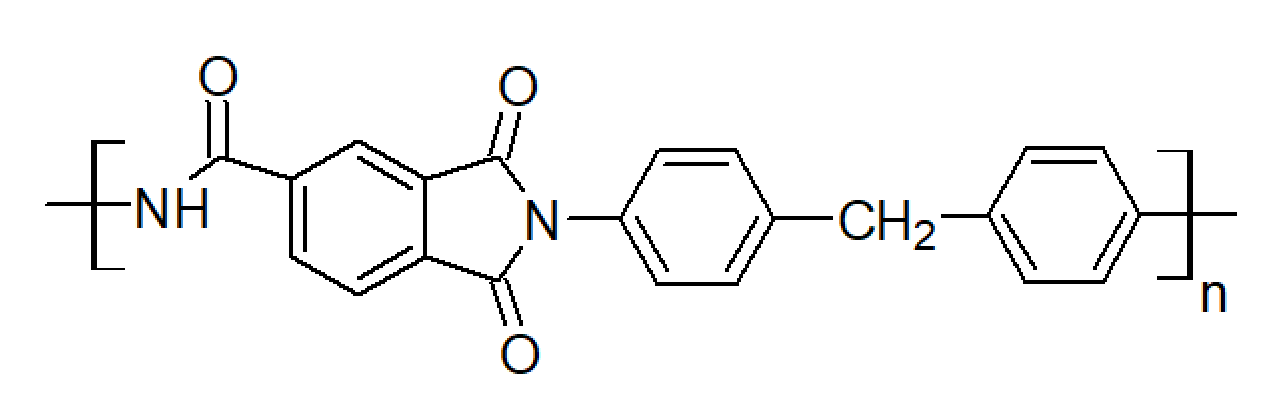

Polyamideimide (PAI) fibers are a class of strong and heat-resistant synthetic fibers. The fiber is produced by polycondensation of a diisocyanate such as phenylene diisocyanate (MDI) with an acid anhydride such as trimellitic anhydride (TMA).

Due to the (mostly) aromatic structure, PAI fibers have excellent heat resistance, low flammability, and good chemical resistance to most organic solvents. They are virtually unaffected by aliphatic and aromatic hydrocarbons as well as chlorinated and fluorinated solvents. Unlike aramid and arylate fibers, they have outstanding resistance to degradation by UV radiation and its thermal conductivity is twice as low as those of aramid fibers.1

The mechanical properties of most polyamideimide fibers are similar to those of aramid fibers but are typically somewhat lower due to the lower proportion of aromatic structures. This type of fiber has very high resistance to abrasion due to its amorphous structure, high elongation at brake, good elasticity and dimensional stability, and medium to high tensile strength and tenacity2 which is maintained over a wide temperature range.

COMMERCIAL PAI Fibers

The world’s only producer of fire resistant polyamide-imide (PAI) fibers for textiles is Kermel, who markets the fiber under the trademark Kermel®.

Applications

Polyamideimide fibers are mainly used for protective clothing such heat resistant safety gloves, flight suits, tank crew coveralls, firerfighting uniforms and industrial workwear for personnel working in hazardous industries. PAI textiles are also used for some technical applications such as hot gas filtration.

1Kermel® polyamide-imide fibre

2The performance of PAI fibers depends to a large degree on the structure and proportion of aromaticity in the polymer backbone.