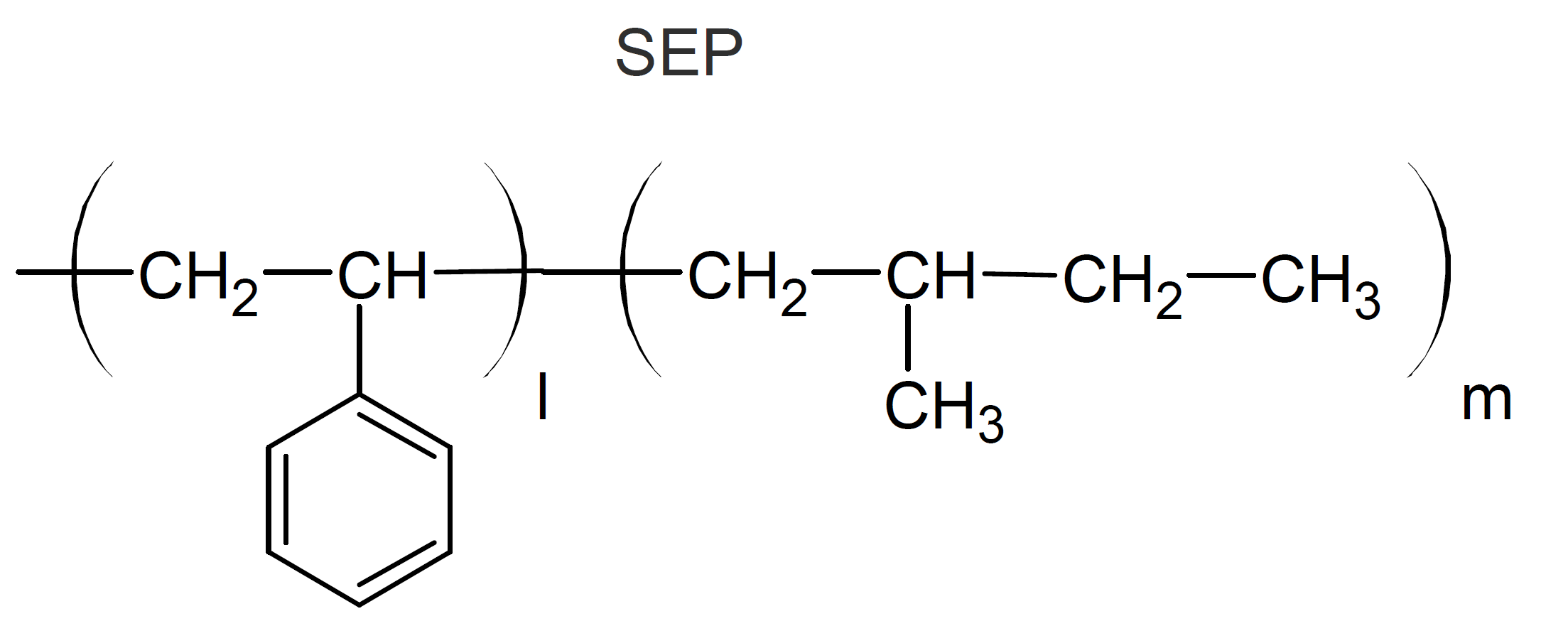

Styrene-Ethylene/Propylene Block Copolymer

Properties and Applications

Poly(styrene-b-ethylene-co-propylene), also known as styrene-ethylene/propylene block copolymer (SEP), is a versatile transparent thermoplastic elastomer which is produced by partial and selective hydrogenating of styrene-isoprene copolymer to improve its thermal stability, clarity and chemical resistance. This copolymer has high transparency, good flow characteristics and is easy to process. It also has improved heat, UV, oil and weathering resistance due to the absence of double bonds in the polymer backbone. A major drawback of hydrogenation is reduced mechanical performance and higher cost.

SEP is often blended with (clear) themoplastics or thermoset resins such as polypropylene and unsaturated polyesters to enhance their performance properties. They are known to improve impact strength and flexibility, both at room and low temperature. Often oil and/or fillers are added to lower cost and/or to further modify the properties. Main areas of application include modified asphalts, adhesives, clear sealants, coatings, automotive products and cable/wire insulations.1

Manufacturers & Distributors

Companies |

Brands |

|