Unsaturated Polyester Resins

Properties and Applications

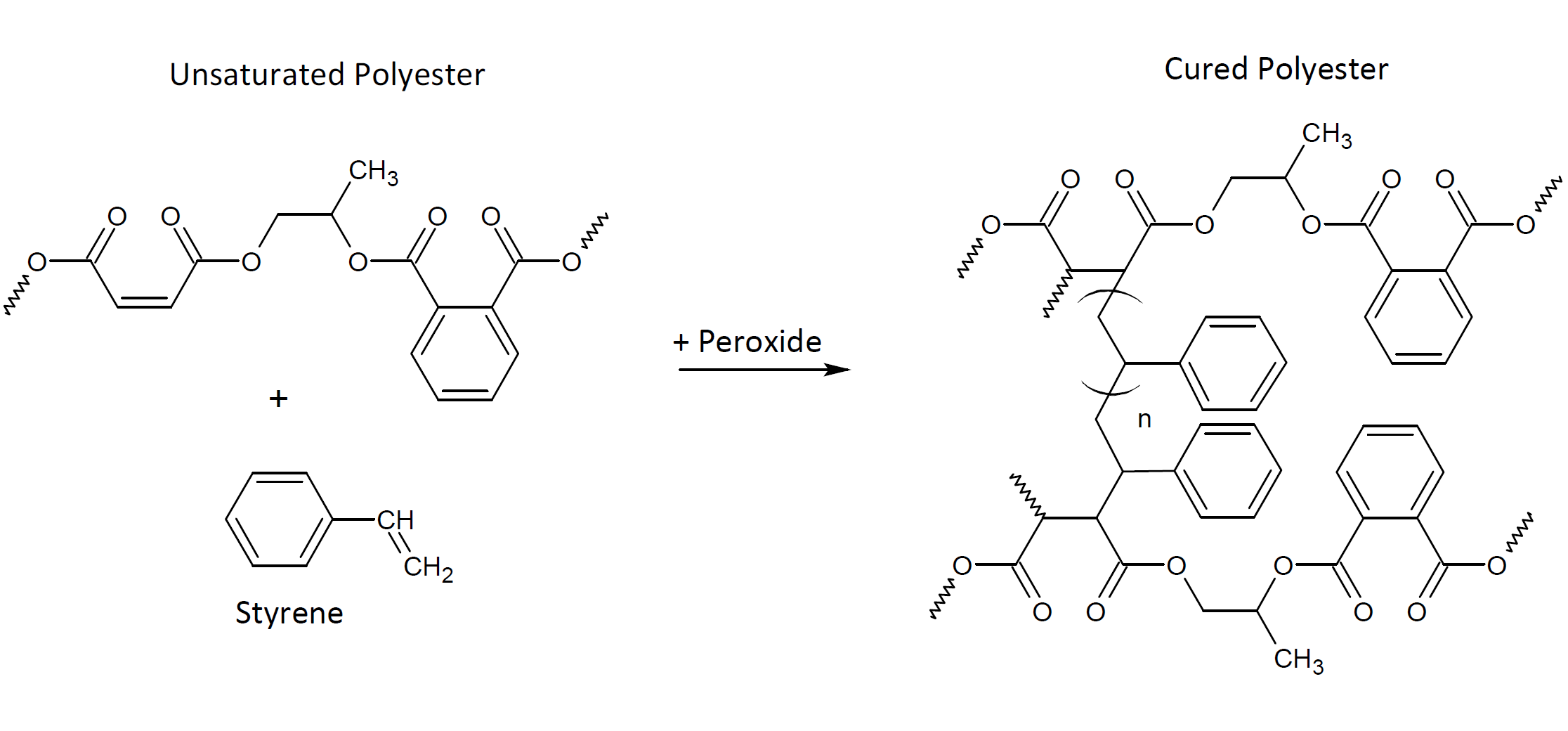

Unsaturated polyesters (UP, UPR) are the third-largest class of thermoset molding resins. They are the condensation product of saturated and unsaturated di-carboxylic acids or anhydrides with alcohols (see Figure below). The most common saturated and unsaturated anhydrides are phthalic and maleic anhydride and the most common alcohol is propylene glycol. The most common vinyl curative is styrene.1 It functions both as a reactive diluent and as a crosslinking agent. It reacts with the double bonds of the prepolymer but also undergoes homopolymerization. The degree of homo- and co-polymerization depends on the reaction conditions, monomer content, and miscibility of the two resins.

The properties of the cured unsaturated resins depend on the types of acids and glycols and their relative amounts as well as on the amount reactive diluent used. In general, these resins form durable structures and coatings when fully cross-linked.

Unsaturated polyester resins are mainly used in the production of fiber reinforced plastics and filled plastic articles, including sanitary-ware, tanks, pipes, gratings, and high performance components for the marine and transportation industry such as closure panels, body panels, fenders, boat hulls/decks and other large glass fiber reinforced parts. Unsaturated polyester resins also find uses in coatings and adhesives.