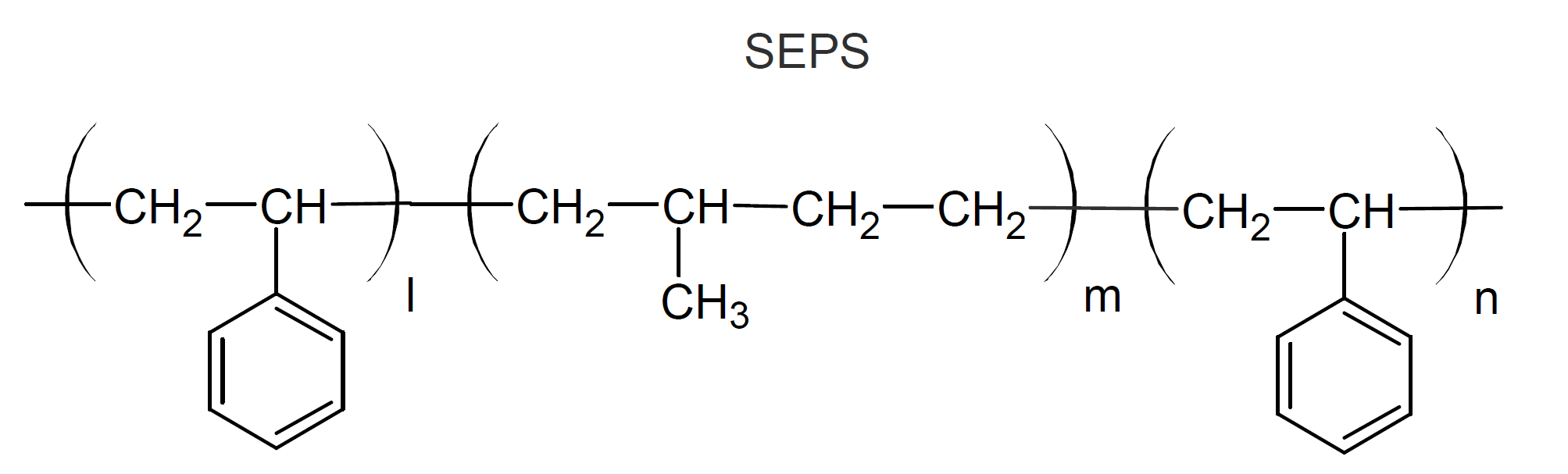

Styrene-Ethylene-Propylene-Styrene Thermoplastic Elastomer (SEPS)

Properties and Applications

Styrene-ethylene-propylene-styrene, also known as SEPS, is a thermoplastic elastomer (TPE) which behaves like rubber without undergoing vulcanization. SEPS is very flexible, has excellent heat and UV resistance and is easy to process. It is produced by partial and selective hydrogenating of styrene-isoprene-styrene copolymers (SIS)1 which improves the thermal stability, weathering and oil resistance, and makes SEPS steam sterilisable.2 However, hydrogenation also reduces the mechanical performance and increases the cost of the polymer.

SEPS elastomers are often blended with other polymers to enhance their performance. Often oil and fillers are added to lower cost and / or to further modify the properties. They are used as impact modifiers for engineering thermoplastics and as flexibilizers / tougheners for clear polypropylene (PP). Other important applications include hot-melt pressure sensitive adhesives and sealants. SEPS can also be used as a modifier for bitumen products such as road paving and roofing applications. The addition of SEPS reduces penetration, temperature susceptibility, and increases the softening point and elastic recovery.3

Manufacturers & Distributors

Companies |

Brands |

|