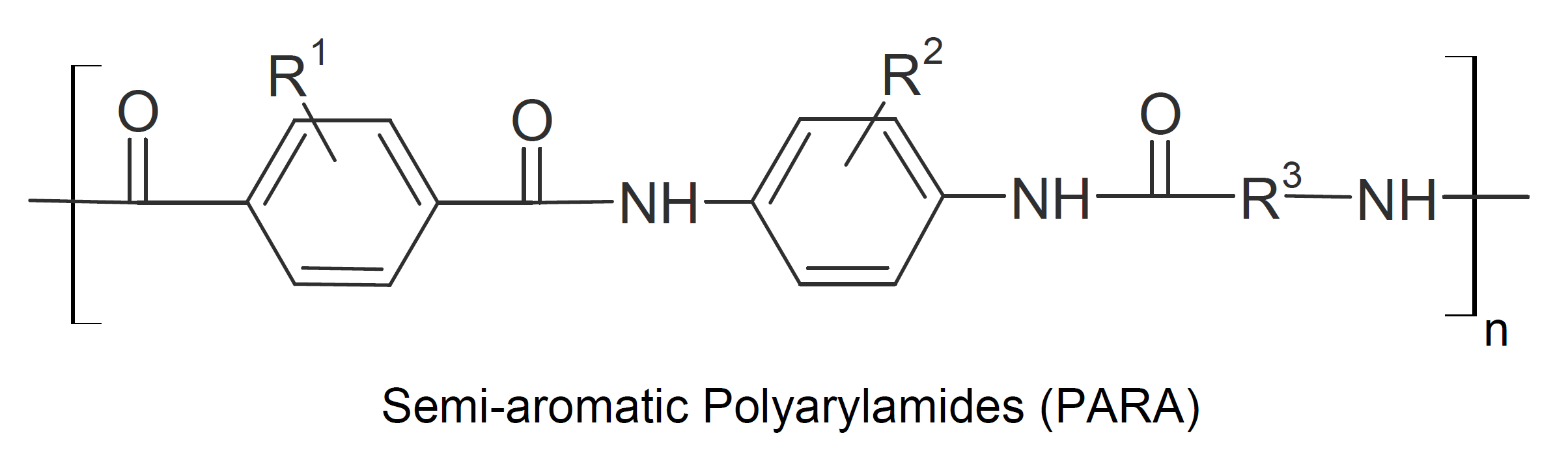

Semi-Aromatic Polyarylamides (PARA)

Properties and Applications

Semi-aromatic polyarylamides (PARA) are semi-crystalline engineering thermoplastics reinforced with glass fibers or mineral fillers. Due to their rigid structure and high crystallinity, they have outstanding thermo-mechanical properties including metal-like strength, high wear, creep and temperature resistance as well as superb rigidity and fatigue resistance. PARAs also have a very low linear coefficient of thermal expansion comparable to that of metals and slow and low water absorption which is much lower than those of standard polyamides such as Nylon 6, and Nylon 6/6.1

This class of polymers accepts high filler loadings which further improve the mechanical strength and stiffness. For example, some grades contain up to 50 - 60% glass fiber reinforcements making these resins ideal for applications where high strength and rigidity is required. Despite a high filler loading, injection molded parts typically possess a smooth and defect-free surface finish superior to many other reinforced resin products. They also have good adhesion properties which is ideal for metallization and painting.2

PARA is ideal for a structural applications across several industries. For example, it is used for indoor and outdoor automotive applications such as mirror and headlamp housings, door handles, and clutch cylinders. In many cases, it can replace metals. Food compliant grades are used in coffee machines and cooking devices where excellent heat and chemical resistance is required and biocompatible grades are used for medical devices and surgical instruments such as scissors and tweezers that need to be sterilized. Applications for flame retardant grades include safety switches, plugs, sockets, lamp housings, connectors and cases for consumer electronics such as laptops, smart phones, cameras and tablets.

Manufacturers & Distributors

Companies |

Brands |