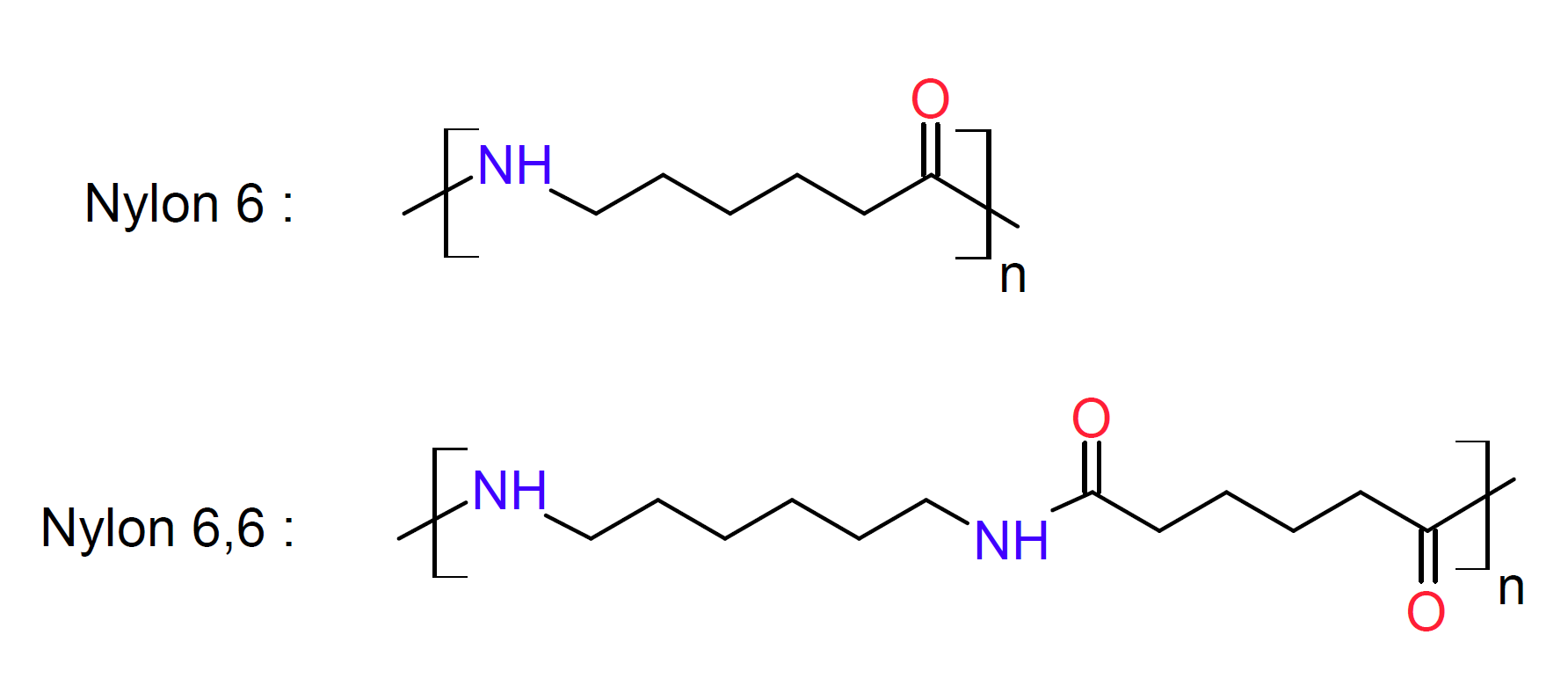

Polyamides (Nylon 6 and 6,6 )

Properties and Applications

Nylon is a generic name for a family of synthetic aliphatic and semi-aromatic polyamides. The two most important polyamides are poly(hexamethylene adipamide) (Nylon 6,6) and polycaprolactam (Nylon 6). Both are amorphous or only moderately crystalline when injection molded whereas films and fibers have a high degree of crystallinity due to mechanical stretching during processing. Nylon 6,6 is usually more crystalline and more ordered than Nylon 6 resulting in slightly different physical properties such as higher melting point, higher modulus, and lower moisture absorption, whereas Nylon 6 has somewhat better ductility and impact resistance. Both types of Nylon have excellent mechanical properties including high tensile strength, high flexibility, good resilience, low creep and high impact strength (toughness). Due to their high melting point of about 500 - 540 K (225 - 265°C) and good fluid resistance, they maintain excellent strength and toughness during exposure to hot, aggressive automotive fluids and to hot air whether humid or dry.1 Polyamides also exhibit excellent resistance to wear due to their low coefficient of friction (self-lubricating) and good chemical resistance including oils, bases, fungi, and many solvents. The main limitation is the strong moisture sensitivity because water acts as a plasticizer which affects the mechanical and thermophysical properties of Nylon.

More than 60 percent of the aliphatic polyamides produced are used in commercial fiber applications. This includes carpets, garments, seatbelts, upholstery, ropes and tire reinforcements. However, fabrics made from Nylons have less wrinkle resistance than cloth made from polyesters and are more expensive. For these reasons, Nylon fibers have lost some market share to PET fibers over the years. Nylons (particularly glass reinforced and impact modified grades) are also important engineering materials. In fact, they are one of the cheapest engineering plastics and find applications in almost every industry and market. For example, in the automotive industry, they are used for wire and cable jacketing, cooling fans, air intake, turbo air ducts, valve and engine covers, brake and power steering reservoirs, gears for windshield wipers and speedometers. Engineering polyamides are also used for power tool housings, valves and vending for various machines and pumps and for many electrical/electronical parts including switches, sockets, plugs and antenna-mounting devices.

Manufacturers & Distributors

Compannies |

Brand Names |