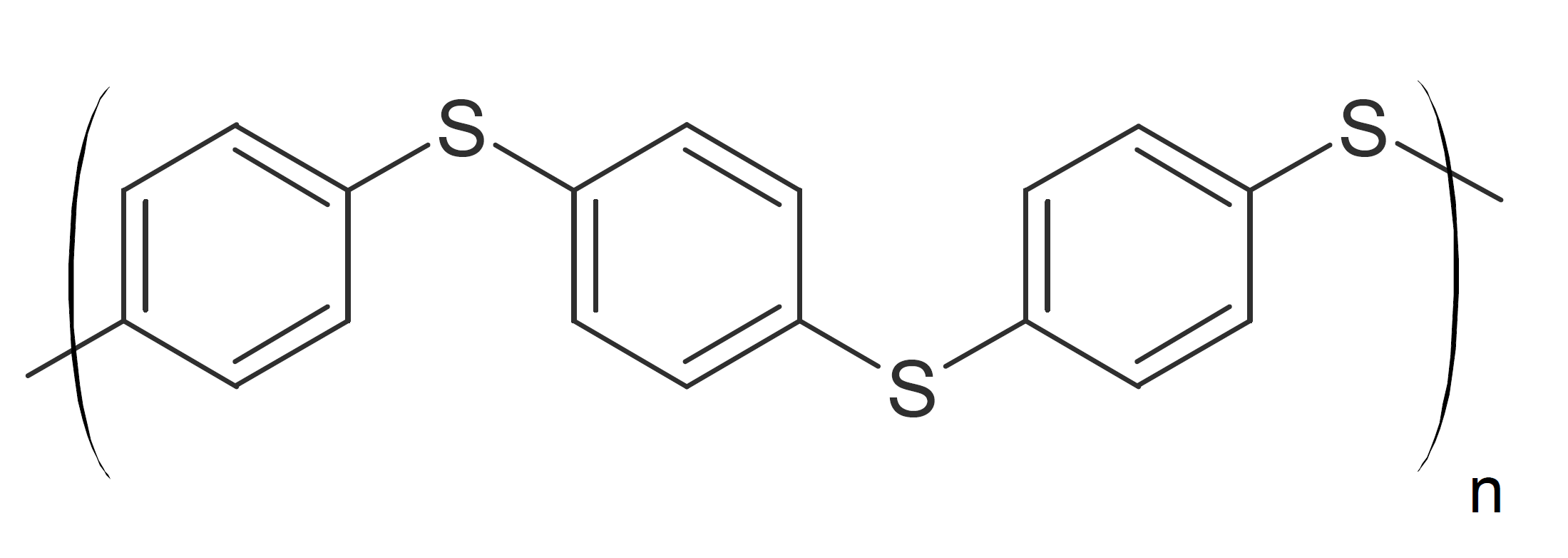

Polphenylene Sulfide Fibers

Properties

Polyphenylene sulfide fibers (PPS) are high-performance, semi-crystalline fibers with exceptional chemical and heat resistance, high dimensional stability, low moisture absorption, and high resistance to hydrolysis when exposed to acids, alkalines, and organic solvents.

This fiber is generally resistant to most common chemicals. It also has excellent creep and property retention at both high and low temperatures but only medium strength comparable to Nylon 66 (staple) and inherent flame retardancy. PPS has a melting point of about 285°C (545°F) and withstands continuous use up to 190°C (375°F).

COMMERCIAL PPS Fibers

The major manufacturers and suppliers of PPS fibers are Celanese, Evonik, and Toray.

Applications

The fiber is used for applications where both excellent heat and chemical resistance is required. For example, PPS is used for high temperature filtration fabrics, conveyor and dryer belts, aerospace thermoplastic composites, and in automotive goods like elastomeric hydraulic hoses that have to withstand demanding environments, to name only a few applications.