Polyxylylene Adipamide Fibers

Properties

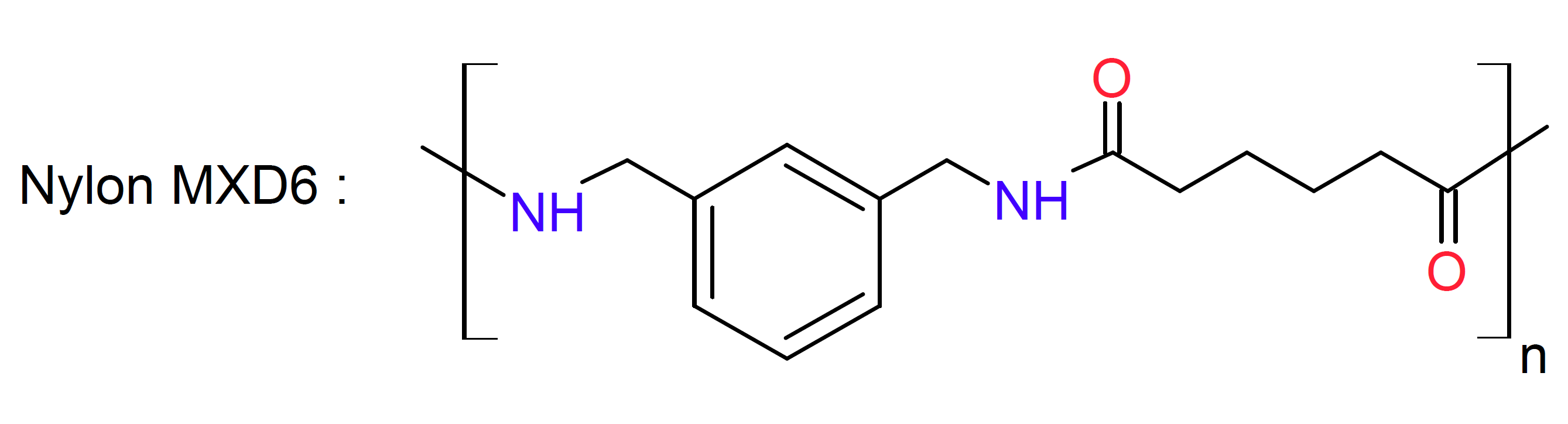

Polyxylylene adipamide, often abbreviated as PA-MXD6, PMXD6 or Nylon-MXD6, belongs to the class of semi-aromatic polyamides produced by polycondensation of meta-xylylenediamine with adipic acid. Monofilament fibers made of this polymer, often exhibit greater heat-resistance, elastic modulus and tensile strength than Nylon 6 and Nylon 66 fibers. Some other major advantages of PA-MXD6 fibers include lower water absorption and greater hydrolytic and flame retardancy1 which leads to greater retention of its superior mechanical properties at high humidity and / or elevated temperatures.

Unlike conventional Nylon fibers, MXD 6 fibers have a partially aromatic polymer backbone resulting in a much higher glass transition temperature, higher packing density, lower coefficient of thermal expansion and higher tensile strength.2 However, semi-aromatic fibers are more expensive than standard Nylon 6 and Nylon 6,6 and thus are only used when superior properties are required.

COMMERCIAL Aramid Fibers

No known manufacturer of MXD 6 fibers.

Applications

MXD-6 fibers have been investigsated my a number of companies including Mitsubishi Gas Chemicals, Celanese, and Invista. However, its use as a textile fiber is restricted due to its high price and limited heat stability. A potential use of flame retardant MXD 6 fibers is protective clothing.