Synthetic Fibers

Synthetic fibers are manmade fibers produced from petroleum- or coal-derived polymers or from natural occuring materials by chemical modification. They are generally semicrystalline polymers that are extruded and drawn in a variety of cross-sectional shapes. The fibers are uniaxially oriented during the melt, dry, or wet spinning process, which give the fibers high tenacity and strength. The synthetic fibers are then converted to yarn by twisting several continuous fibers together to a uniform yarn with all filaments more or less alligned parallel to the yarn axis.

Commercially produced fibers can be classified as cellulosic and noncellulosic fibers. Cellulosics are derived from naturally occuring cellulose through chemical reactions and processing.

The most important types of cellulose based synthetic fibers are cellulose acetate (Acetate), regenerated cellulose (Viscose Rayon), Cuprammonium Rayon (Bemberg), and saponified acetate (Rayon).

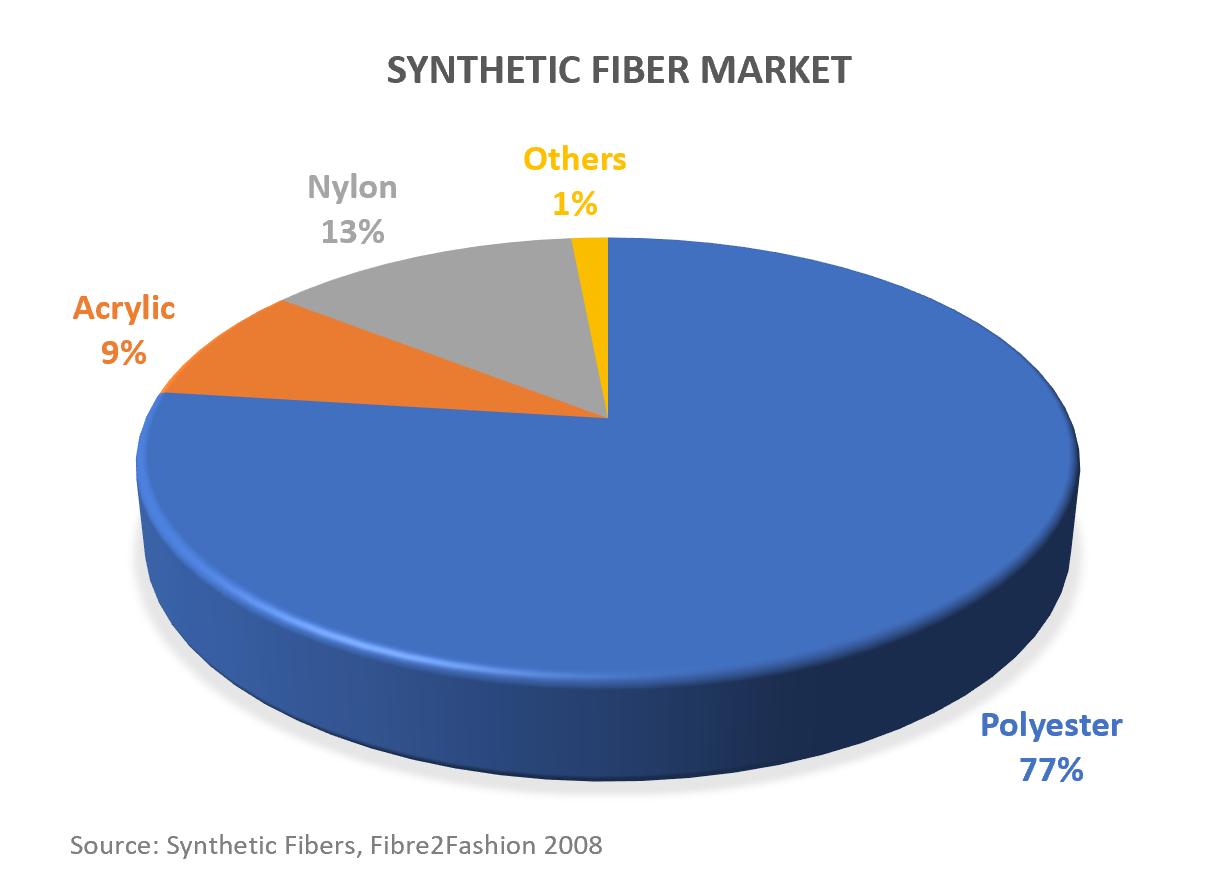

Cellulosic fibers represent only a small fraction of the fiber market. Many other synthetic fibers are in use today. Common non-cellulosic fibers include Nylon (1931), Olefin (1949), Acrylic (1950), Polyester (1953) and Spandex (1959). Of these, Polyester, Nylon and Acrylic are the most important fibers accounting for more than 80% of the world fiber market.

Synthetic fibers are generally more durable than most natural fibers. In addition, the properties of synthetic fibers and fabrics can be easily taylored to the application by varying the chemical composition and the process conditions. For example, they can be flexible and elastic or stiff and strong or they can have high or low water absorbancy. Compared to natural fibers, synthetic fibers are usually more water, stain, heat and chemical resistant. In general, natural fibers are more sensitive to chemical degradation than synthetic fibers because they are biodegradable, can be attacked by various bacterias and fungi (mildew), and break and wear down over time, whereas most synthetic fibers are non-biodegradable.

However, synthetic fibers have also some disadvantages; most of these are related to their low melting point and/or their chemical composition. For example, certain synthetic fibers are prone to heat damage by hot washing. They also have a stronger tendency to electrostatic charging when rubbing against other materials, and they are not always skin friendly, and, in some cases, can cause allergic reactions. Some commercial fibers, like polyester and nylon, do not absorb sweat as much and quickly as natural fibers. For these reasons, synthetic fibers are sometimes blended with natural fibers, like cotton and wool.

Synthetic fibers are sometimes spun together with natural fibers to achieve certain blended properties. For example, blends of cotton and polyester can be strong, wrinkle and tear-resistant, and have reduced shrinkage. They also have better water, tear and environmental resistance compared to most plant-derived fibers. However, cotton - polyester blends are less breathable than cotton and trap more moisture while sticking to the skin. They are also less flame resistant and can melt when ignited.

Unlike natural fibers, the majority of synthetic fibers are not naturally biodegradable and thus decompose only very slowly which can cause a significant problem to the environment if textiles made of polyester are not fully recycled or properly disposed of.