AeM – Ethylene Acrylic Elastomers

Properties

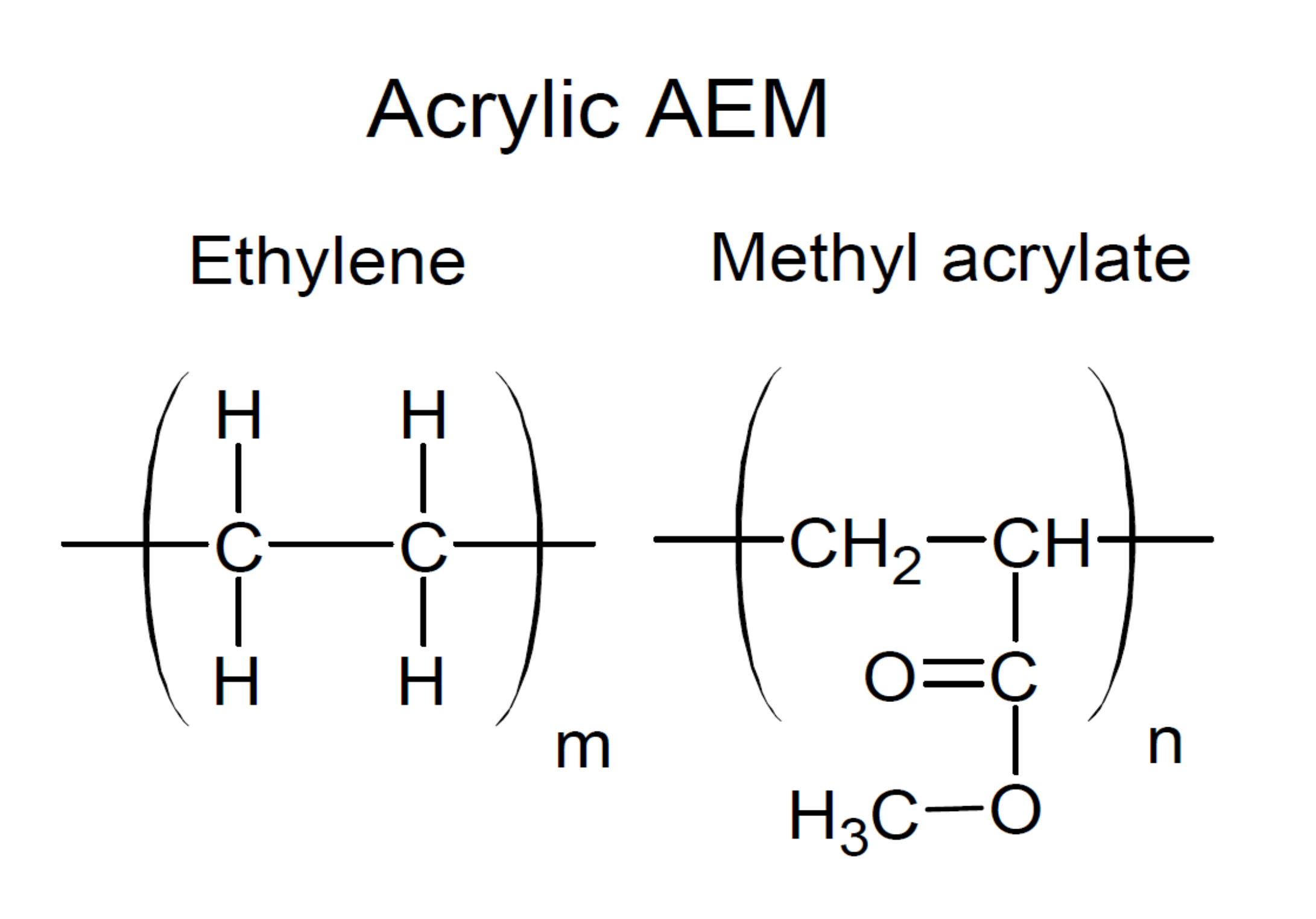

Ethylene acrylate copolymers, also called AEM rubbers, are synthetic elastomers composed of ethylene and acrylic monomers. The ethylene repeat units impart good low temperature properties, while the acrylic portion improves swelling resistance in non-polar oils. The combination of a saturated backbone with polar side groups also provides good resistance to heat, ozone (weathering), and many chemicals.

In general, AEM’s resistance to ozone and weathering is superior to nitrile rubber (NBR) and its cold temperature performance is better than that of ACMs. Besides excellent heat and ozone resistance, AEMs have outstanding vibration dampening and good dynamic and abrasion properties over a wide temperature range. However, water and moisture resistance is only fair, as is the resistance to dilute acids and alkalis. Furthermore, AEMs are much more expensive than most standard elastomers including NR, NBR, CR, EPDM, and SBR.

COMMERCIAL AEM Elastomers

An important manufacturer and supplier of AEM rubbers is DuPont.

Applications

AEM elastomers are primarily used where combined resistance to ozone, heat and oils is required. They are sometimes a good alternative to more expensive heat resistant elastomers such as fluorocarbon polymers (FKM), silicones (VMQ) and fluorosilicones (FVMQ) for elevated temperature applications (< 150 °C). However, AEMs are not recommended for exposure to aromatic hydrocarbons, gasoline, brake fluids and phosphate esters.

Typical applications include automotive transmission / power steering seals and O-rings that have to be resistant to transmission fluids and many other common automotive lubricants and hydraulic fluids. Other applications include diaphragms, plumbing seals, boots, hoses, vibration mounts, pads, isolators and custom molded rubber goods and parts.

The typical continuous operating temperature range is -30°C to 150°C (up to 175°C for limited periods of time).