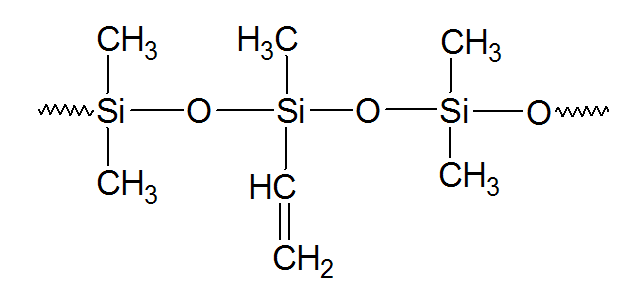

VMQ – Silicone Rubber

Vinyl Methyl Silicone

Properties

Silicone elastomers are ideal for high and low temperature applications. They have high heat and oxidative stability, outstanding low temperature flexibility, and are resistant to many chemicals, weathering, ozone and sunlight (UV). However, they are not resistant to super-heated steam, and their physical properties are generally low but are usually retained at higher temperatures. They also have poor gas permeability and low resistance to mineral oils and hydrocarbon solvents.

VMQ rubbers are extremely heat resistant. The typical working temperature range is -60°C to +250°C, whereas some special grades will withstand temperatures up to 300°C. However, hot steam (> 120°C) can cause hydrolysis and severe degradation.

COMMERCIAL VMQ Elastomers

Important manufacturers and suppliers of VMQ rubbers are Eriks, Wacker, Eastern Seals, and BlueStar

Applications

Silicone rubbers are rather expensive in comparison to most other elastomers and are, therefore, only used when excellent resistance to chemicals, oxygen, weathering and/or flexibility at (very) low temperatures is required. They are also used when food/bio compatibility is needed.

Silicone rubbers are widely used in the pharmaceutical, medical, electrical, automotive and aerospace industry. Typical applications include surgical implants, wound dressings, mold making, wire and cable insulations, gaskets, seals, and tubings. Silicone elastomers are also used in pressure sensitive adhesives.