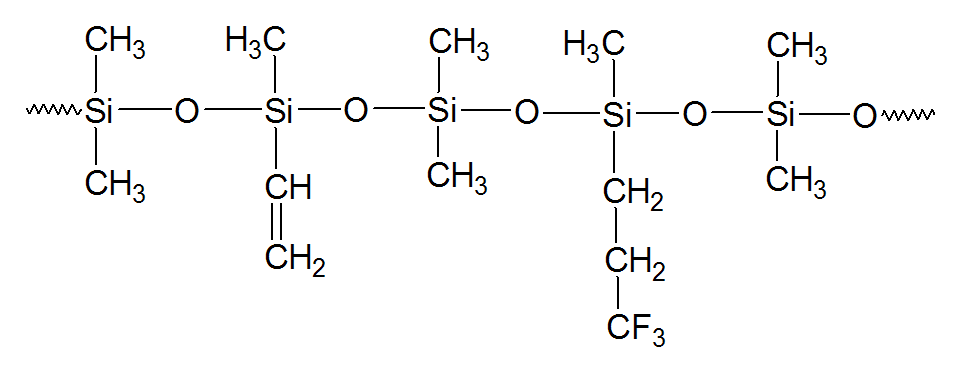

FVMQ - Fluorosilicone Rubber

(Fluorovinylmethylsiloxane Rubber)

Properties

Fluorosilicone or fluorovinylmethylsiloxane rubber (FVMQ) has many of the attributes of silicone. For example, FVMQ rubbers have similar mechanical and physical properties and offer excellent chemical resistance to dilute acids and alkalines, and non-polar fluids like petroleum oils, hydrocarbon fuels, diester and silicone oils. However, they have only fair resistance to polar fluids like alcohols and poor resistance to ketones, aldehydes, amines, and (non-petroleum based) brake fluids. They also have lower hot air resistance when compared to silicone rubbers (VMQs).

Like silicone elastomers, they have high heat and oxidative stability, outstanding low temperature flexibility, and are resistant to heat, ozone and sunlight (UV). They also offer a similar wide operational temperature range, which is much wider than that of fluorocarbon rubbers.

COMMERCIAL FVQM Elastomers

Important manufacturers and suppliers of Fluorosilicone rubbers are Dow Corning, Wacker, and Momentive.

Applications

Fluorosilicones are used for sealing applications in the aerospace industry requiring resistance to hot fuels, oils, and diester based lubricants. They are often a good choice for static sealing systems for a wide temperature range. Their use is normally limited to static applications due to poor abrasion resistance, relatively low tear strength and only fair flex-cracking resistance, although some grades exist that have improved or even good flex cracking resistance and compression set.