Polyvinyl formal (Vinylec)

Properties and Applications

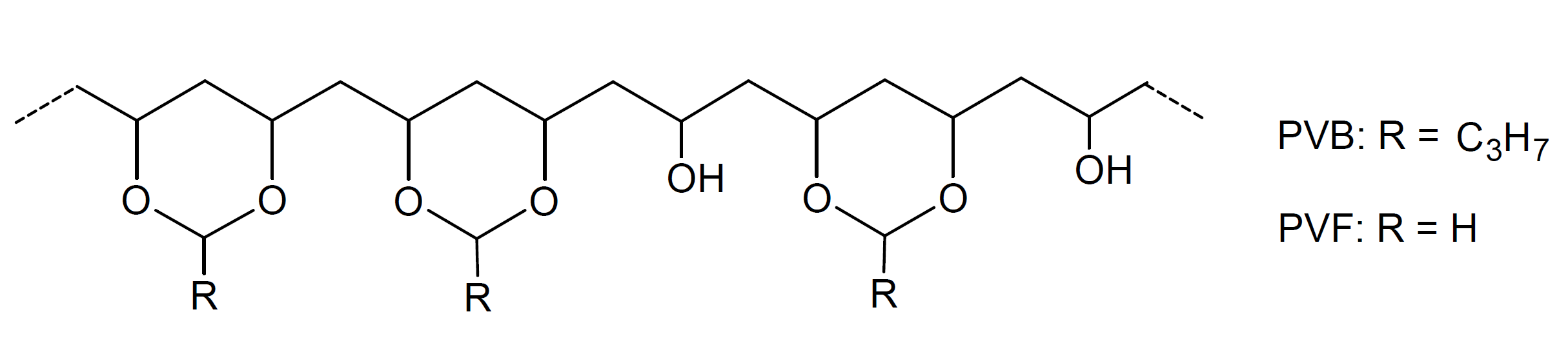

Polyvinyl formal, also known as Formvar or Vinylec, is a thermoplastic resin that has outstanding toughness, flexibility, moldability, as well as good abrasion, chemical and heat resistance. The polymer is produced by hydrolysis of poly(vinyl acetate) to poly(vinyl alcohol) which is subsequently converted to polyvinyl formal by acetalization with formaldehyde.

The properties of vinyl formal resins, such as solubility and compatibility with binders and plasticizers, depend on the degree of acetalization. An increase of the number of formal groups in the polymer usually improves water resistance and solubility in non-polar solvents. Polyvinyl formal can also be cross-linked. Its cross-linking capacity depends on the number of residual hydroxyl groups which can undergo condensation reactions with phenolic, epoxy, and melamine to produce high quality solvent resistant coatings and films.

Thermoplastic polyvinyl formal resins are supplied as free-flowing powders. They are available in different grades having different molecular weights and different melt viscosities to meet various end usages. A major application of vinyl formal resins are wire enamels to provide electrical insulation on magnetic wires. They are often blended (and cross-linked) with other resins such as phenolics and PVA to achieve optimal performance. Other applications include solenoid bonding, metal priming, heat-curable adhesives for metals as well as general toughening of brittle resins such as epoxies, and phenolics.