Poly(Vinyl Alcohol) (PVOH)

Properties and Applications

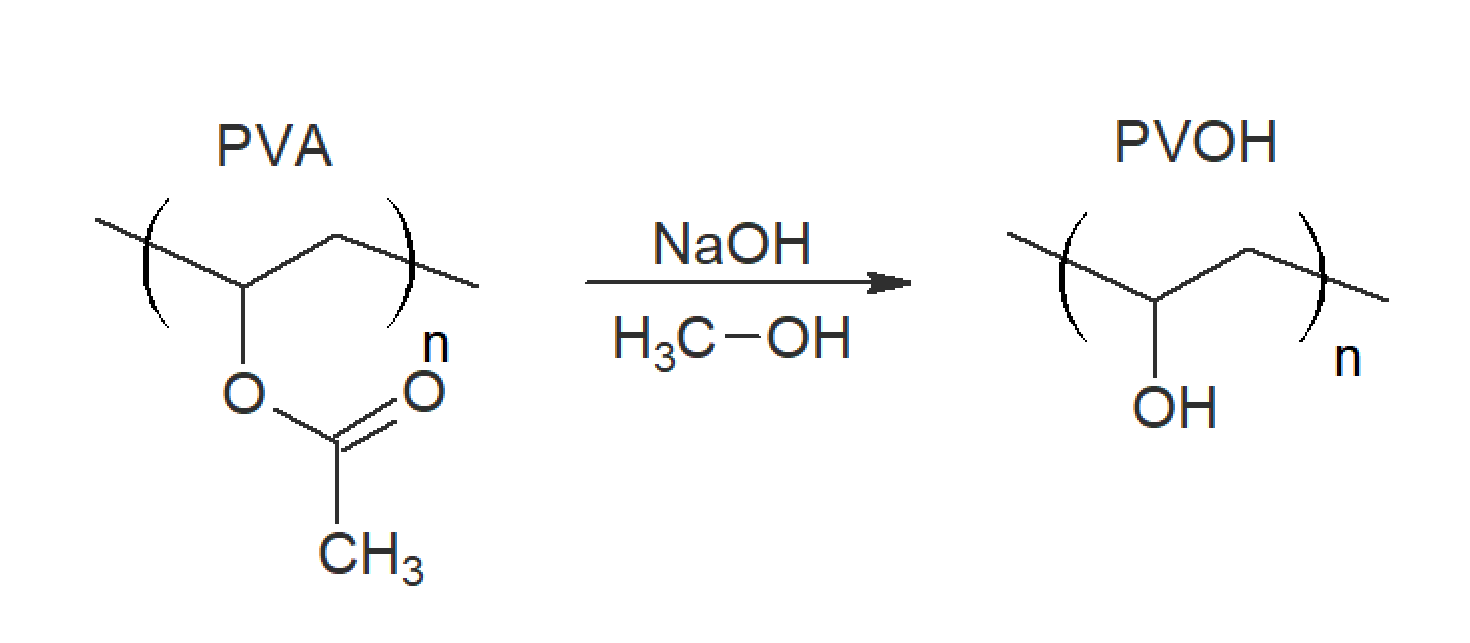

Polyvinyl alcohol (PVOH, PVA, or PVAL) is produced by hydrolysis of polyvinyl acetate. The amount of hydroxylation determines its physical and mechanical properties. The dry polymer is a hard, colorless and odorless crystalline thermoplastic with a Tg of about 375 K. It is highly water soluble, fully biodegradable but resistant to solvents and oils, and has exceptionally good adhesion to cellulose and other hydrophilic surfaces.

PVOH is extensively used as a binder, emulsifier and thickening agent for a large number of products including paper, remoistenable adhesives, textile finish, paper surface treatment as well as cosmetics, food and pharmaceutical products.1 PVOH is also used as a (water soluble) packaging material. Films made from PVOH have outstanding heat-sealing properties and exceptional barrier properties to gases such as oxygen, nitrogen, and carbon dioxide. Furthermore they are fully biocompatible, biodegradable and nontoxic, making them especially suited for packaging of food, drugs, and cosmetics.