Urea-Formaldehyde Resin (UF)

Properties and Applications

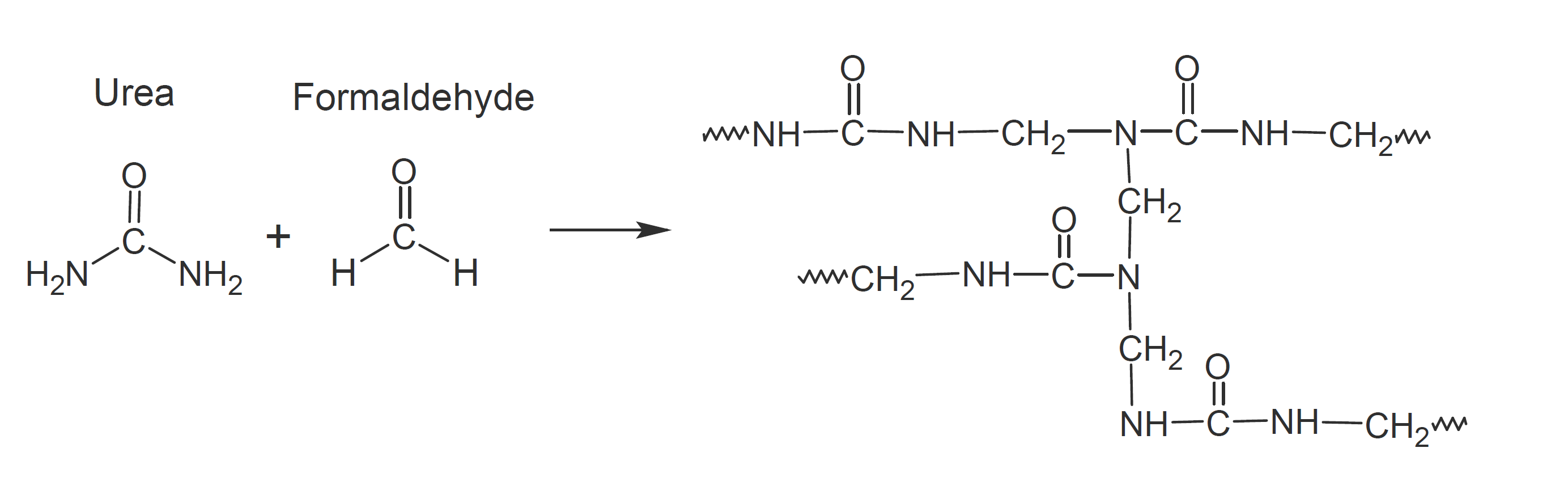

Urea-formaldehyde (UF), also called aminoplasts, are highly crosslinked, rigid and crystalline-like thermosetting plastics produced by the reaction of formaldehyde with urea. UF resins are noted for their high strength, cost effectiveness and fast cure. Infact, UF resins are some of the fastest curing resins available. At elevated temperatures, they can be cured in as little as two seconds. A major drawback of urea- formaldehyde resin compared with other thermosetting wood bonding resins such as phenoplasts and polymeric diisocyanates, is the lack of moisture resistance especially at elevated temperatures. Furthermore, the reversal bond-forming reactions can lead to the release of formaldehyde.2

Urea-formaldehyde resins find applications in adhesives, coatings, laminates, and moulding compositions. Most of the produced UF resins are consumed by the wood industry for bonding particleboards, medium-density fiberboard, and hardwood plywood. They are also used as adhesives for decorative laminates. Other applications include wet laid fiberglass mats, air filtration, coated and bonded abrasives. Due to the lack of moisture resistance, UF adhesives and binders are mainly used for the manufacture of wood products intended for interior use only.

Manufacturers & Distributors

Companies |

Brands |