Resorcinol-Formaldehyde & Phenol-RF Resins

Properties and Applications

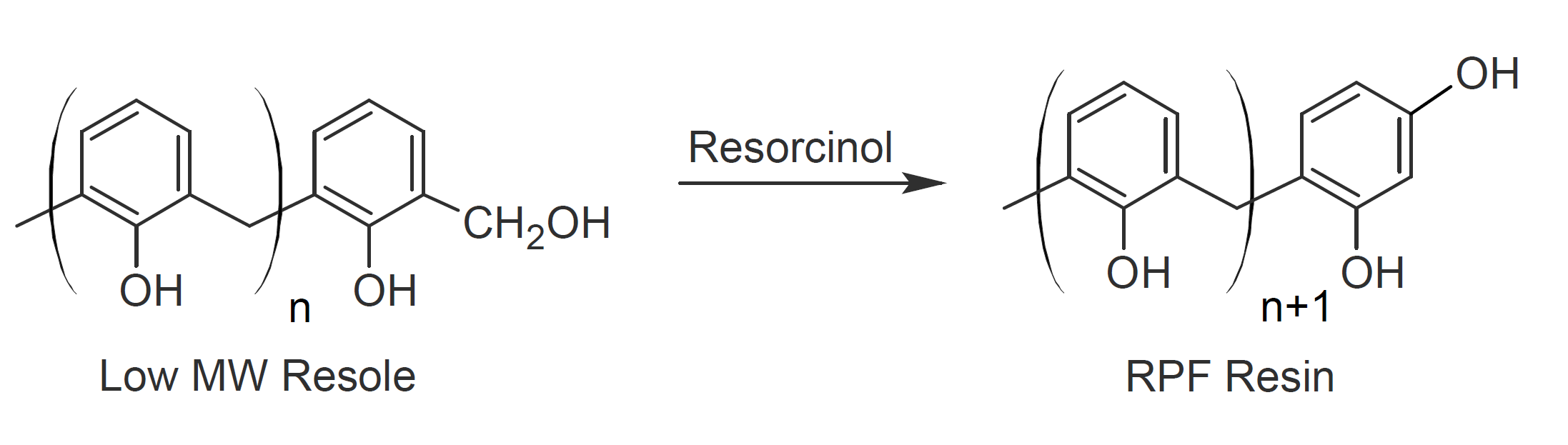

Resorcinol-Formaldehyde (RF) are synthetic thermosetting resin systems obtained from polycondensation of formaldehyde with resorcinol (1,3-dihydroxybenzene). Like phenolic resins, resorcinol resins form very durable and strong bonds with excellent humidity, water and corrosion resistance. However, unlike phenolic resins, RF resins can be cured at room temperature because these resins cure about ten times faster than and phenolic resins. A major drawback is the high price of resorcinol. To lower cost, but to maintain ambient cure, resorcinol is typically copolymerized with phenol and formaldehyde (PRF resins).

RF and PRF resins are used in wood bonding applications where high bond strength, water resistance and room temperature cure are required or desired. For example, they are used in the production of outdoor furniture, boat building and for laminated beams in load-bearing wooden structures. RF and PRF resins are also used as bonding agents in vulcanizable rubber products to enhance adhesion between polar plastics and rubber. For example, they are used as tire cord dip resins, particularly for rayon and nylon cords which provide strength and stability to the sidewall and tread as well as maintain air pressure.