Polyphthalate Carbonate (PPC)

Properties and Applications

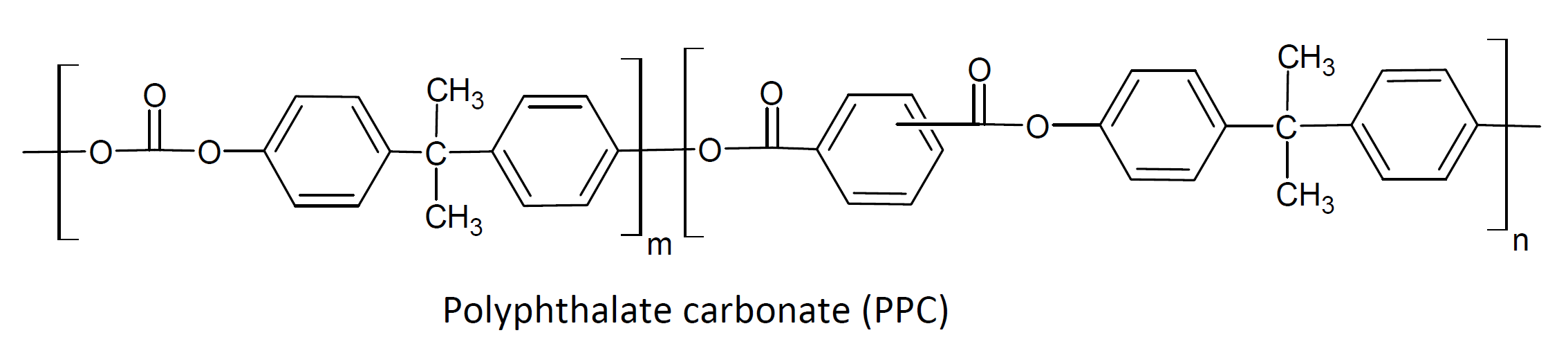

Polyphthalate carbonate, commonly abbreviated as PPC, is another amorphous, lightweight and high heat resistant polycabonate. It can be prepared from the condensation of phosgene, isophthaloyl dichloride and/or terephthaloyl dichloride with bisphenol A.1 Its structure is shown below.

Like common polycarbonate (PC), PPC can be molded and thermoformed, and has similar attractive properties including high light transmittance, good dimensional stability as well as excellent impact resistance and moderate creep resistance. But compared to regular polycarbonate, PPC offers much improved resistance to yellowing and hazing from prolonged exposure to ultraviolet radiation. However, like regular PC, PPC has poor scratch and solvent resistance which can be improved when coated with silicones.

PPC resin and its blends with regular polycarbonate are used in the production of transparent, ultraviolet radiation stable sheets and films that find applications in the glazing industry. Other (potential) applications include sun glasses, face shields, and automotive parts such as instrument and exterior panels.

Manufacturers |

Brand Names |

1D.C. Clagett, D.W. Fox, S.J. Shafer, P.D. Sybert; US Patent 4,918,149; Polphthaltecarbonate/Polcarbonate Resin Blends, Genral Electric 1990.