Polycarbonate (PC, PC/ABS, PC/ASA)

Properties and Applications

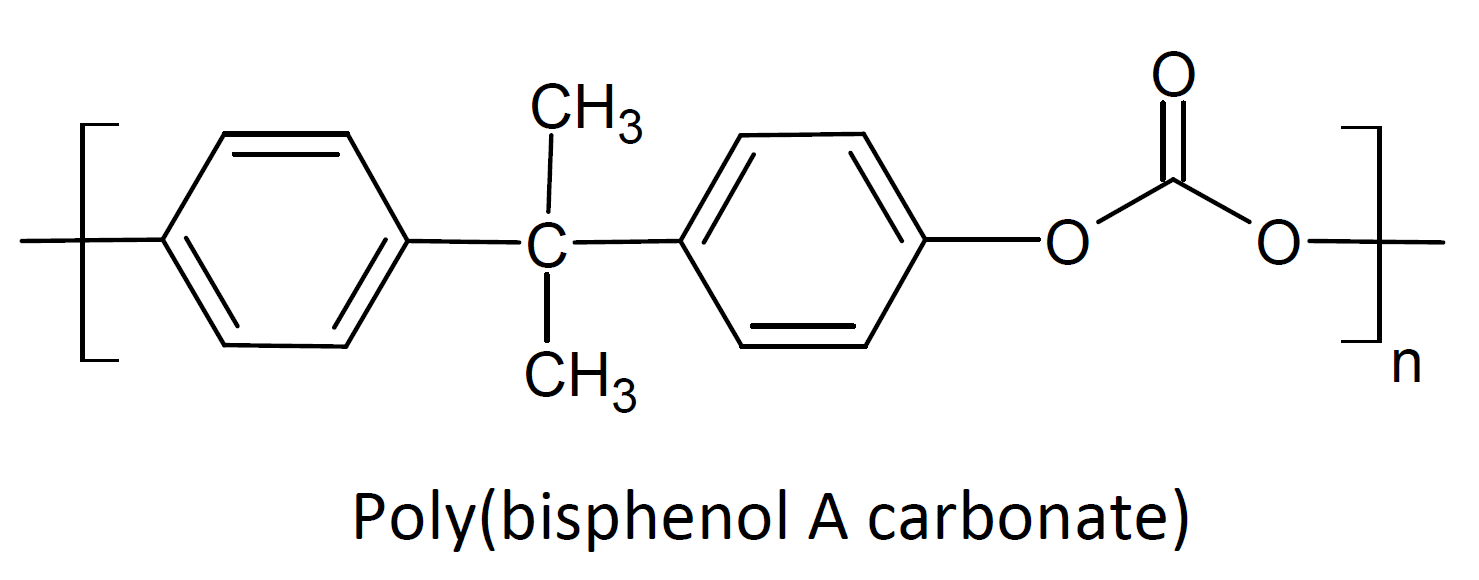

Poly(bisphenol A carbonate), commonly referred as polycarbonate and abbreviated as PC, is one of the largest sales volume engineering thermoplastics. It is an amorphous polymer that can be easily molded and thermoformed, and that has many attractive properties. For example, It is well known and appreciated for its exceptional high light transmittance, impact toughness as well as good dimensional stability and creep resistance. PC also possesses high electrical and heat resistance, is biologically inert, and can be readily recycled. However, PC has poor scratch and solvent resistance and a tendency to yellow when exposed to UV light for prolonged time. To improve its scratch and solvent resistance, polycarbonate parts are frequently coated with silicones.

PC is sometimes blended with other resins to further enhance its properties. For example, PC/ABS blends combine the excellent low temperature properties and high processability of ABS with the superior mechanical properties and heat resistance of polycarbonate. These blends possess high toughness and impact strength at temperatures below those of PC but are stronger and have a higher maximal service temperature than ABS.

Polycarbonate finds many uses across almost every industry. Major applications include safety helmets, digital discs (CDs, DVDs, and Blu-ray), sun glasses, face shields, power tools, appliance housings, and automotive parts such as instrument and exterior panels, wheel covers, glazing for windows and doors.

PC-ABS and PC-ASA blends find applications in the automotive and electronic device industry. They are widely used for computer, monitor, printer and mobile phone housings and for interior and exterior car parts such as seat belt covers, front grilles, roof rails, spoilers, and mirror housings.1

PC has a continuous upper service temperature of 80°C or greater and retains useful mechanical properties between -40°C and 135°C (Tg = 145°C).