Polyvinyl Butyrals (PVB)

Properties and Applications

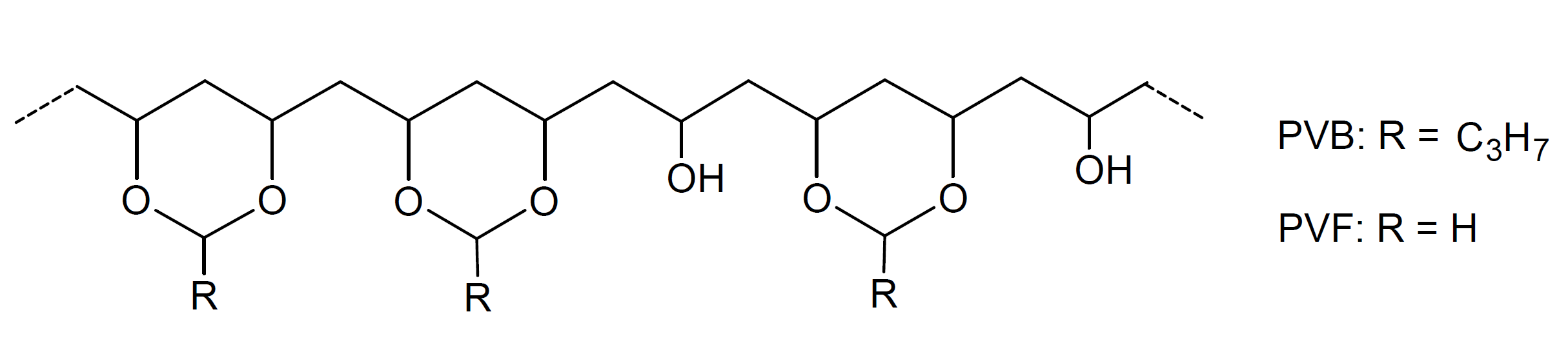

Polyvinylbutyral (PVB) is a transparent, tough and flexible thermoplastic with high optical clarity and good adhesion to a large number of substrates. It is manufactured from polyvinyl alcohol by reaction with butyraldehyde and formaldehyde.

Thermoplastic polyvinyl butyral resins are supplied as free-flowing powders. The properties of these grades like their solubility and compatibility with binders and plasticizers depend on the degrees of acetalisation and polymerization. An increase of the number of butyral groups in the polymer usually improves water resistance and solubility in non-polar solvents. PVB can also be cross-linked. Its cross-linking capacity depends on the number of residual OH groups in the polymer which can undergo condensation reactions with phenolic, epoxy, and melamine resins as well as with isocyanates to produce high quality solvent resistant coatings and films.

Due to its good light resistance and excellent transparency, PVB is often used as an interlayer for fracture-resistant and shatterproof glass in architectural and automotive fields. PVB resins are also extensively used as binders in paints, printing inks, lacquers, primers, ceramic/metal powders, and adhesives.