Polyhydroxyalkanoates (PHAs)

Properties and Applications

Polyhydroxyalkanoates (PHA) are melt-processable,

semi-crystalline thermoplastics produced from microorganisms by

fermentation of renewable carbohydrate feedstocks. PHAs are 100%

biobased, truly biodegradable and biocompatible, and could be an attractive environmental-friendly

alternative to fossil-based thermoplastics such as PE and PP.

In fact, some grades of additivated PHA are similar in their material properties to polypropylene (PP), and possess good resistance to moisture and aroma barrier properties.1

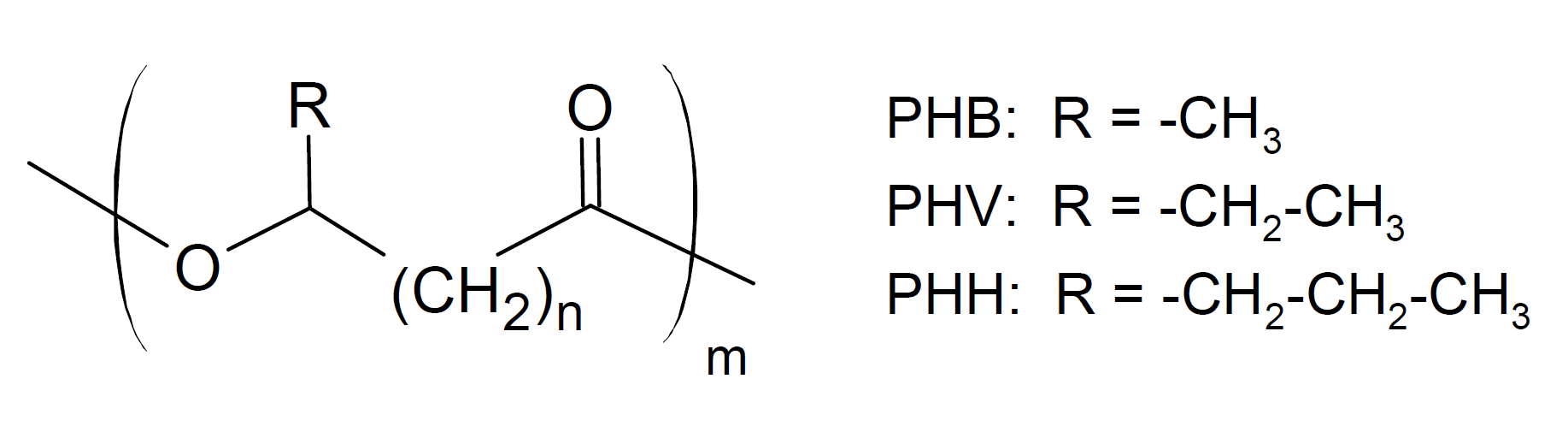

The three most important polyhydroxyalkanoates are poly(3-hydroxybutyrate) (PHB),

polyhydroxyvalerate (PHV), and

polyhydroxyhexanoate (PHH) with a chemical structure as follows.

PHB is probably the most popular PHA. However, unmodified PHB resin has a relatively high melting point of about 160 to 180 °C and is difficult to process due to its narrow processing window. To improve its processability and mechanical properties, it is often copolymerized with other hydroxyalkanoates (PHBV, PHBH) or blended with other plasticizers and other polymers such as polyvinyl acetate (binders), polyvinyl alcohol and polylactic acid (PLA).2 In addition, nucleation agents can be added to lower its crystallinity.1

Several companies are involved in the production of PHAs. The market is currently relative small but is expected to grow significantly. Typical applications of PHAs include disposable tableware articles like drinking cups, cutlery, trays, food plates and food containers. Some other (potential) applications include soil retention sheething and other agriculture films, waste and shopping bags, and the use as a packaging material in general. PHAs can also be spun into fibers which could be used for the manufacture of woven and non-woven biodegradable one-use fabric articles such as surgical sutures. Other (potential) biomedical applications include drug delivery systems (microcapsules or microspheres) and biodegradable implanted medical devices.