Polyethylene (LDPE, LLDPE, HDPE)

Properties and Applications

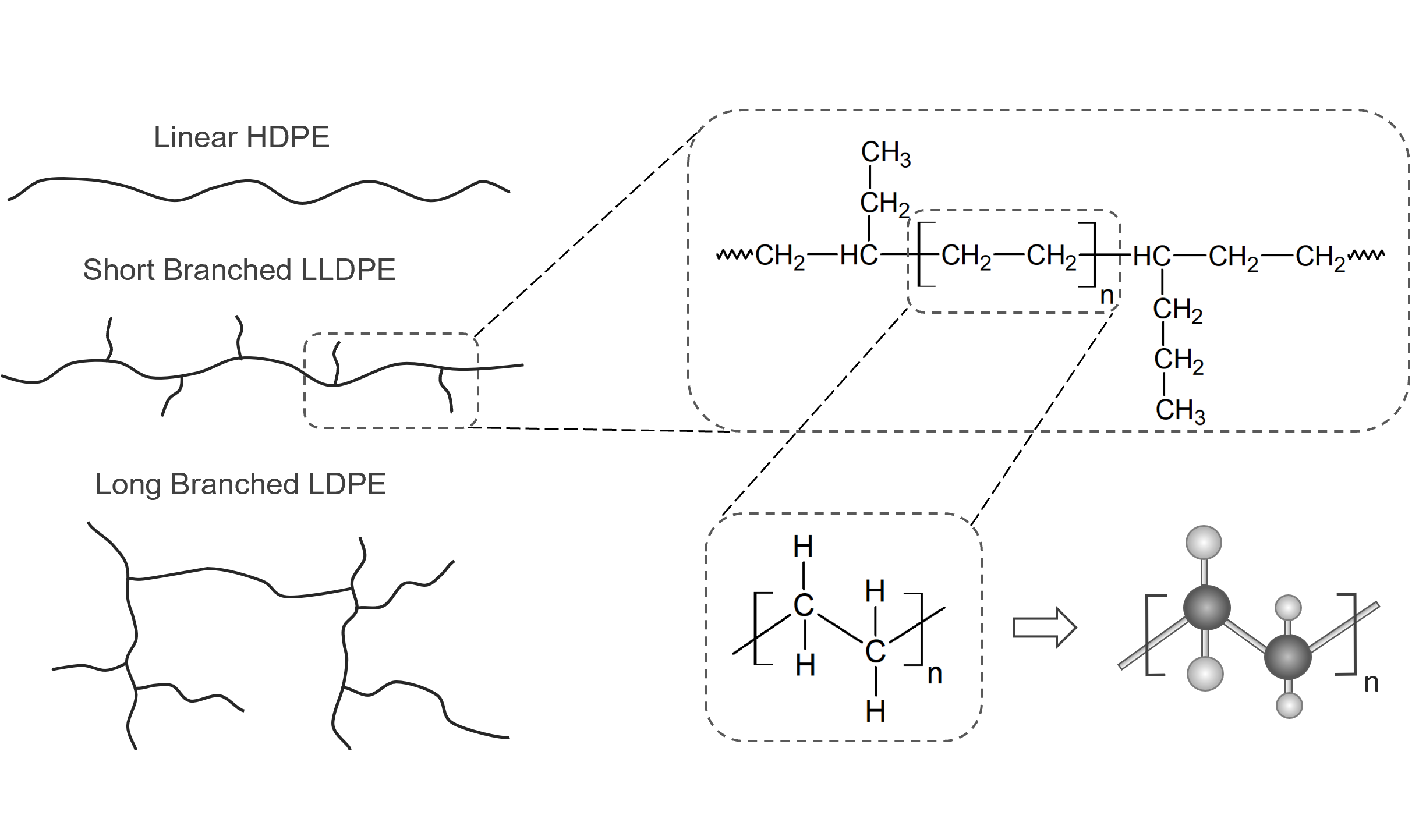

Polyethylene (PE) is the largest volume commodity thermoplastic in the world, followed by polypropylene. A variety of different grades are produced. The three most important grades are low-density (LDPE), linear low-density (LLDPE), and high-density polyethylene (HDPE). On a volume basis, HDPE is the most important grade, followed by LLDPE and LDPE. These three PE resins differ in molecular weight, crystallinity (density), and branching:

HDPE has a much lower degree of branching than LDPE which results in a much higher degree of crystallinity typically in the range of 70 % to 80 % depending on molecular weight and thermal history. The crystals are also larger and more uniform than those of LDPE. HDPE is much denser, more rigid and less permeable than the other types of polyethylene with the exceptions of HMWPE and UHMWPE. It is much stronger and harder than LDPE but it is also less tough and flexible and has lower stress crack resistance.

LDPE is a very flexible and tough polyethylene. Compared to HDPE, it has a higher degree of short and long side-chain branching which results in lower density and crystallinity as well as in greater flexibility and toughness. However, LDPE has a significantly lower tensile strength, heat deflection temperature and melting point than HDPE. Compared to LLDPE, it has smaller crystallites due to longer side and subside branching. The degree of crystallinity is usually in the range of 40 % to 55 % depending on branching and thermal history.

LLDPE has similar strength as HDPE but is much more flexible. The polymer chains have a large number of short branches, which are shorter and more abundant than those of LDPE. It also has a narrower molecular weight distribution than LDPE. Both increases the degree of crystallinity which results in higher tensile and impact strength and greater puncture resistance compared to LDPE. This type of low density polyethylene can be processed into thinner films with better environmental stress crack resistance than HDPE and LDPE.

Polyethylene is one of the cheapest thermoplastics. It is relatively easy to process, chemically inert, and has many attractive properties. These characteristics and its low price make it the ideal plastic for a multitude of (consumer) plastic products such as containers, buckets, pipes, toys, covers, lids, plastic bags, stretch wraps, sheets, films, bottles and extrusion coated paper cartons. The packaging industry is by far the largest consumer of polyethylene. It has replaced metals, glass, paper and other materials in many packaging applications.

Manufacturers & Distributors

Companies |

Brands |