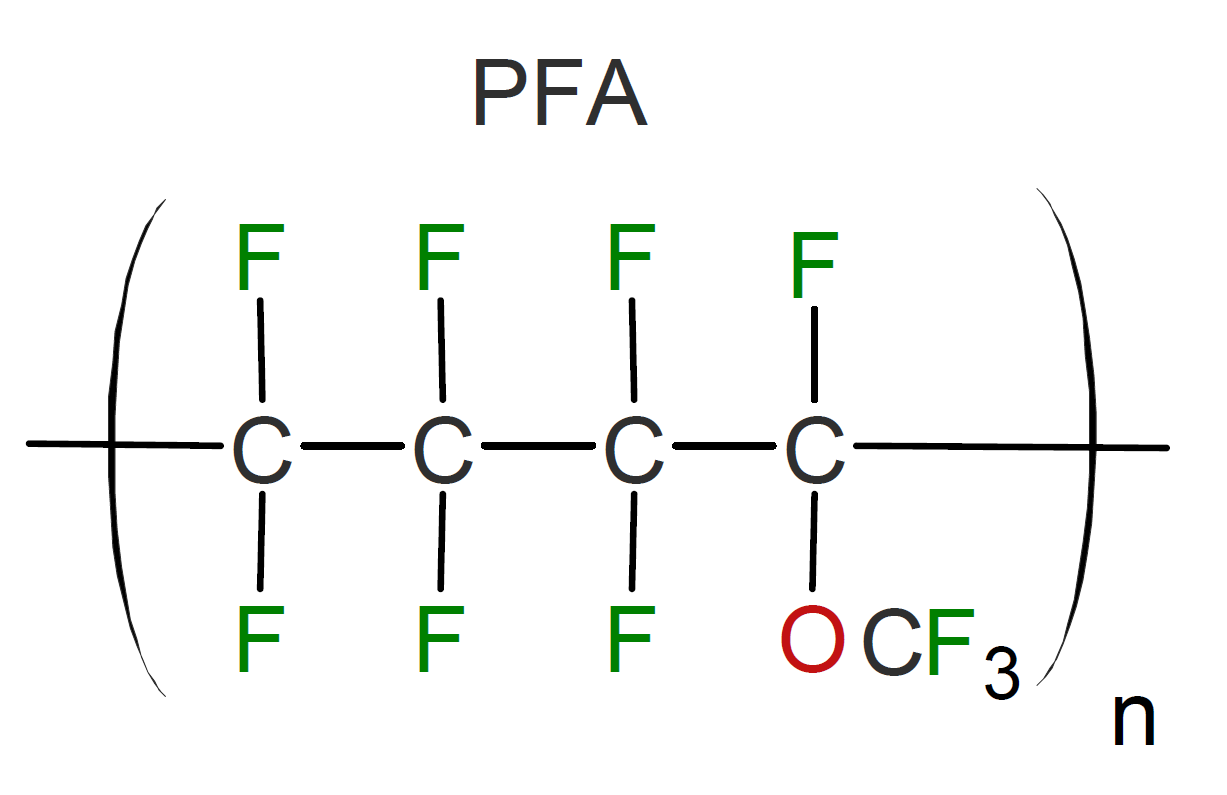

Perfluoroalkoxy Alkanes (PFA)

Properties and Applications

Perfluoroalkoxy alkane (PFA) is a transparent copolymer of tetrafluoroethylene and perfluoroalkyl vinyl ether. Its properties are very similar to those of polytetrafluoroethylene (PTFE) including high resistance to chemicals, UV, and temperature; outstanding slip and release properties; and excellent electrical properties including high dielectric strength, low dissipation factor, and low dielectric constant. However, unlike PTFE (Teflion), this fluorinated polymer is fully melt-processable by conventional molding methods including extrusion, compression, blow, transfer, and injection molding. Its maximum continuous use temperature is approximately 260°C (500°F).1

PFA is often an excellent choice when outstanding chemical resistance, high toughness and flexibility, very low coefficient of friction and exceptional dielectric insulation is required or desired. It is molded and extruded into a multitude of parts including extruded wire insulation, tubing, protective film and sheet linings, and pump housings which are used in abusive environments. PFA is also used as an inert and non-stick material for semiconductor wafer carriers, medical devices, and food processing and packaging equipment.

Companies |

Brands |