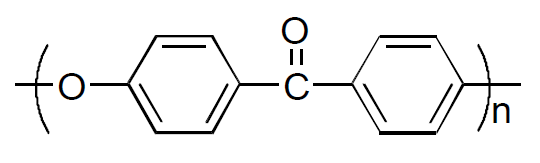

Polyetherketone (PEK)

Properties and Applications

Polyetherketone (PEK) is a semi-crystalline, high-performance engineering thermoplastic. The benzene rings connected to ketone groups provide high modulus and long-term thermal oxidative stability whereas the ether linkages provide toughness, ductility and facilitate ease of processing.1

PEK posesses high thermal dimensional stability, low flammability, outstanding chemical resistance, and excellent mechanical properties over a wide temperature range. Compared to PEEK, the mechanical and physical properties remain almost constant at up to 30°C higher temperatures. PEK is also known for its good creep resistance, excellent fatigue properties and outstanding chemical resistance, a combination of properties not often found in other crystalline high-performance plastics.

PEK is often a good choice for applications where vibrational or cyclic loading is expected and where components have to withstand high mechanical loads even at high temperatures for long periods of time. It is widely used in the aerospace, aircraft, and automotive industries for structural components with high load requirements like bushes, gears, shafts, bearings, and ultra small rotational precision parts. PEK is also used in the medical industry for body implants and in the electrical industry for wire and cable insulation.