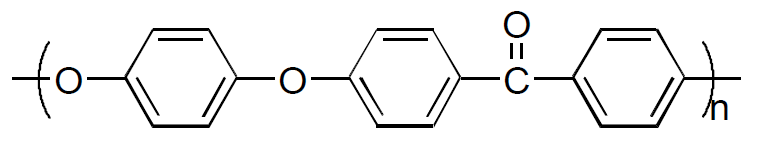

Polyether Ether Ketone (PEEK)

Properties and Applications

Polyetheretherketone (PEEK) is a semi-crystalline, cololess high-performance engineering thermoplastic. The aromatic ring structure connected to ketone groups provides high modulus and long-term thermal oxidative stability whereas the ether linkages provide toughness, ductility and facilitate ease of processing.

PEEK posesses high thermal stability, excellent chemical resistance, and performs over a wide temperature range. PEEK is also known for its exceptionally high resistance to hydrolysis in hot water and steam and can be used continuously up to 500°F (260°C) with little or no permanent loss of its physical properties.1 However, it exhibits only moderate resistance to weathering due to damage caused by UV radiation.

Because of PEEK’s excellent mechanical properties, including high stiffness, high toughness, outstanding wear resistance, and long-term creep and fatigue resistance, mechanical parts made of this material can replace steel in many applications. In fact, PEEK is among the worlds highest performing thermoplastics and is widely used in the aerospace, automotive, and chemical industries for a multitude of engineering parts such as gears, bushes, friction bearings, shafts, ball valve seals, and small precision (rotational) parts. Its bio-compatibility, bio-inertness, and high hydrolytical stability makes PEEK also ideally suited for surgical body implant applications.

Manufacturers |

Brand Names |