Polybenzimidazole (PBI)

Properties and Applications

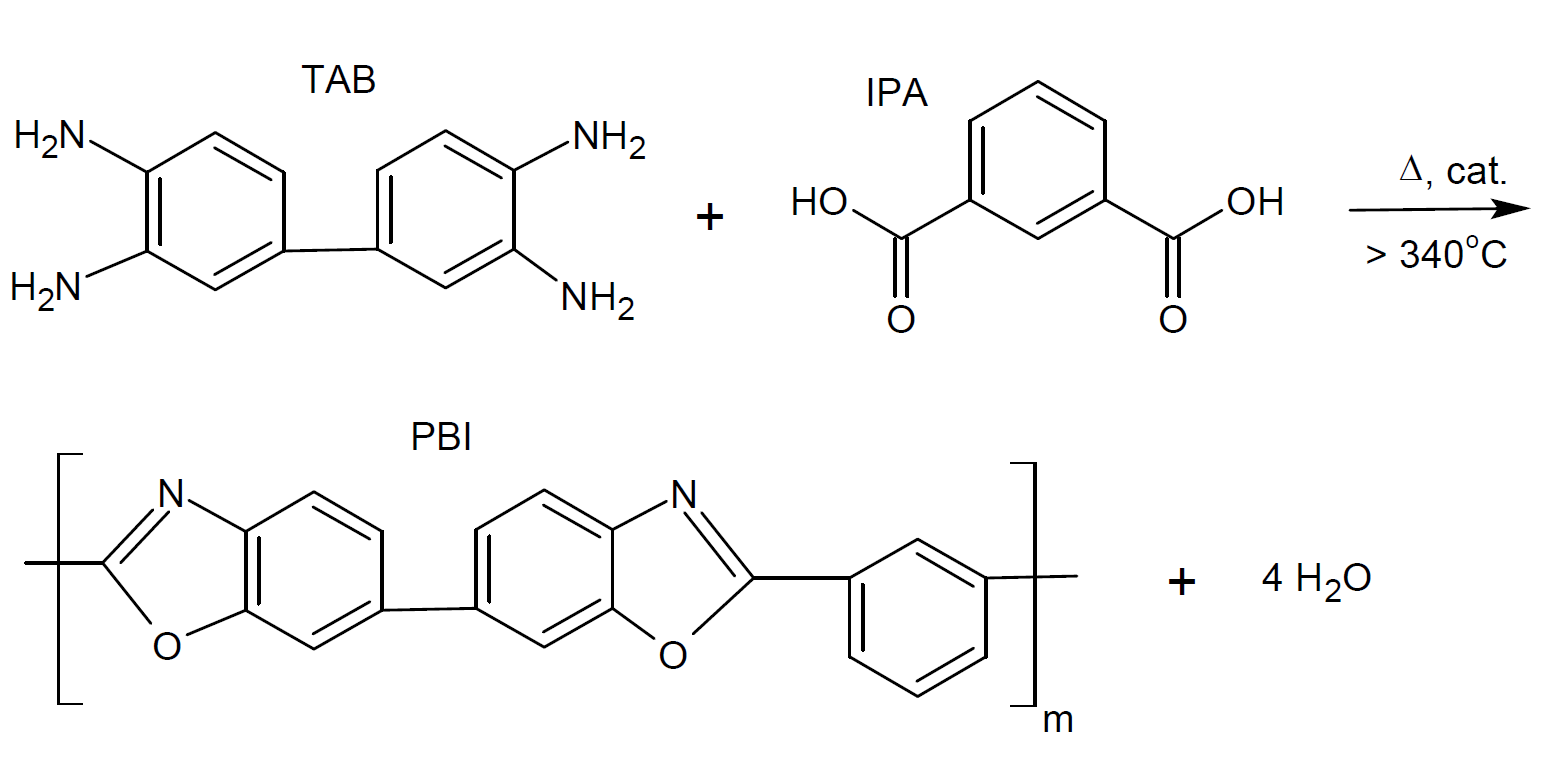

Polybenzimidazoles (PBI) are extremely heat-resistant heterocyclic thermoplastics. They are prepared from an aromatic tetraamine and an aromatic dicarboxylic acid or a derivative of it. One of the most common PBIs is poly[2,2′-(m-phenylene)-5,5′-bibenzimidazole] which can be produced by condensation of isophthalic acid with 3,3’,4,4’-tetraamino diphenyl which undergoes spontaneous cyclization at temperatures > 340 °C in an inert atmosphere:1

Polybenzimidazole is quite expensive and difficult to manufacture but

has outstanding properties. It is one of the highest performing

engineering thermoplastics on the market and offers one of the

highest heat resistance and service temperature of any unfilled

thermoplastic. It has a glass transition temperature of about 425°C

(800°F) and no melting point and its heat deflection temperature at

264 psi (1.8 MPa) is about 815°F (435°C). It also possesses

outstanding chemical resistance.

PBI has a very low level of ionic impurities and does not outgas (except water). These characteristics makes

it ideally suited to semiconductor applications (vacuum chamber

applications). However, its extreme hardness makes it difficult to machine. In most cases, diamond tools are recommended or required. Other

applications include heat resistant apparels, contact seals, membranes for various separation processes, insulator bushings, and thermal isolators.

Manufacturers & Distributors

Companies |

Brands |