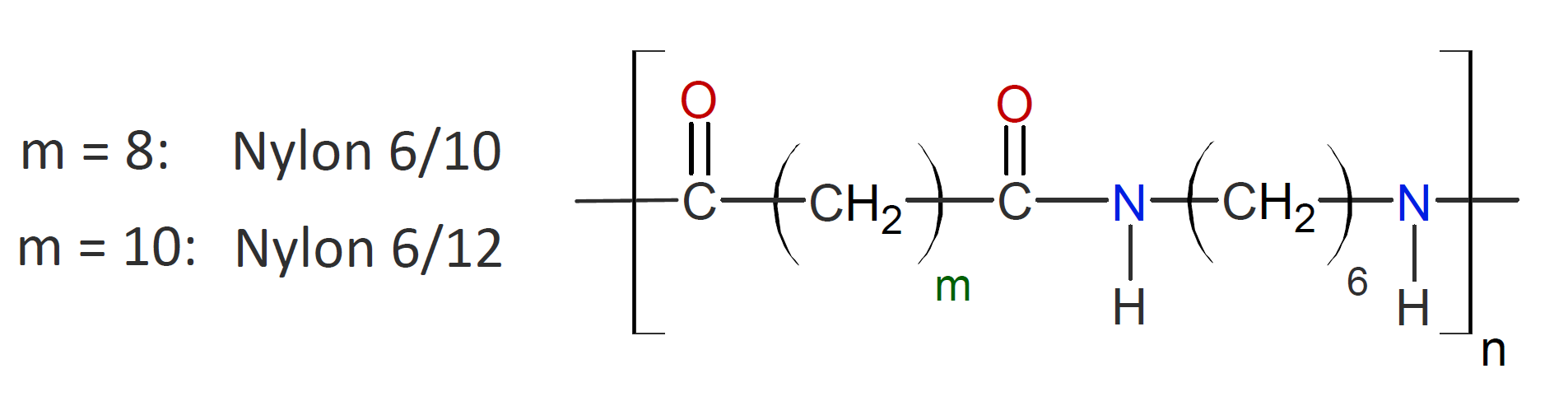

Polyamide 6/10 and 6/12 (Nylon 6/10 & 6/12)

Properties and Applications

Polyamide 6/10 and 6/12 (also called Nylon 6/10 and 6/12) are thermoplastic polymers made from condensation polymerization of n-(do)decanedioic acid (or their diacid chlorides) and 1,6-hexanediamine. These two types of polyamides have high impact strength1, excellent wear resistance, good electrical insulation properties and high chemical resistance, and much lower moisture absorption than the standard polyamides PA 6 and PA 6,6 and thus do not swell as much. They are also less sensitive to stress cracking. On the downside, they have lower flexural and tensile strength, lower heat deflection temperature (HTP), as well as greater mold shrinkage than standard Nylon due to their lower crystallinity. They are also more expensive.

Nylon 6/10 and 6/12 are available in various grades, including unreinforced, reinforced with glass fibers or mineral fillers, as well as impact modified or plasticized grades. They are used in many industries and for a wide range of applications, including zip fasteners, gears, cams, electrical insulators, precision parts, cable jackets, and filaments for brushes. They are often chosen for applications where high heat, moisture, and chemical resistance as well as good dimensional stability is required.

Manufacturers |

Brand Names |