Oxetane Resins (Epoxy Modifiers)

Properties and Applications

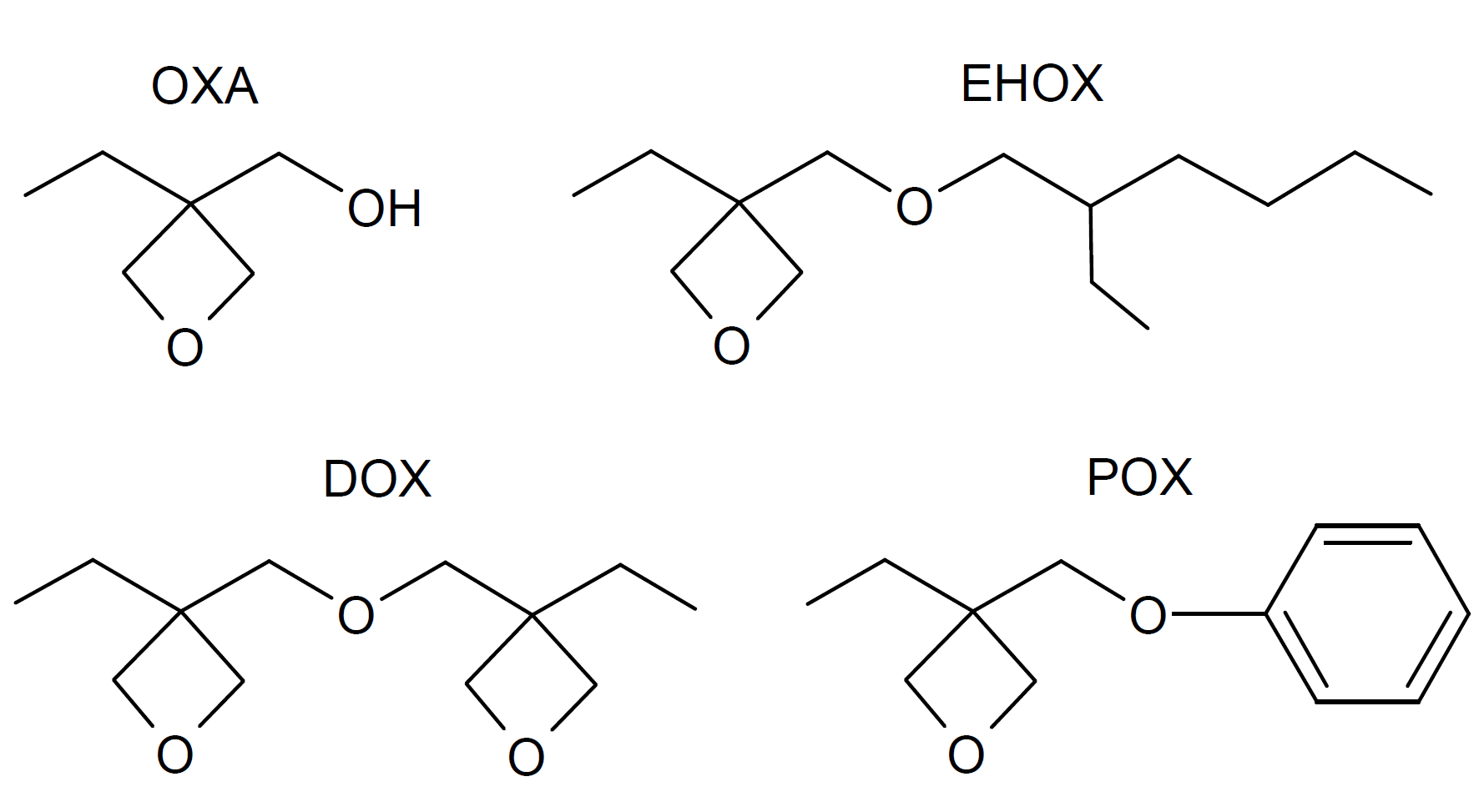

Oxetanes are low molecular weight resins having one or more four-membered rings of three carbon atoms and one oxygen atom. They are the closest homologs to epoxides, but historically have received much less attention than epoxy resins due to their higher cost. A variety of mono- and difunctional oxetanes have been synthesized which polymerize readily. Two very common oxetanes are 3-ethyl-3-hydroxymethyl oxetane (OXA), and 3-Ethyl-3-phenoxymethyloxetane (EHOX) (see below).

These resins have typically a much lower viscosity than standard epoxies (DGEBA) and epoxy-novolacs and thus can function as reactive diluents and modifiers for epoxy products. Monofunctional oxitanes have typically the lowest viscosity. These diluents, however, tend to reduce mechanical strength because they terminate growth of the polymer, and thus reduce the crosslink density of the epoxy product which, in turn, reduces high temperature performance. Difunctional oxitanes, on the other hand, have little effect on cross-link density. They are often a good choice when moderate viscosity reduction with good retention of mechanical properties at elevated temperatures are desired.

Oxetane resins are mainly used for cationic UV curing resins. They are highly reactive and readily polymerize by ring-opening polymerization.1 When blended with conventional epoxy, they increase cure speed and boost performance by increasing the conversion and molecular weight. Typical applications are cationic UV curable products such as food can coatings, adhesives, flexo inks, and IR shieldings.