Acrylonitrile Butadiene Rubber (NBR)

Properties and Applications

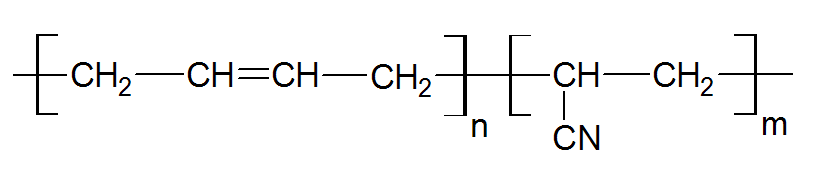

Acrylonitrile butadiene rubber, also called nitrile rubber and usually shortened to nitrile or NBR, are important high volume elastomers. They are statistical copolymers of acrylonitrile and butadiene produced by free-radical emulsion polymerization of butadiene with 15 to 45 percent acylonitrile:

Nitrile rubbers have good abrasion and chemical resistance including mineral oils, fuels, and other nonpolar compounds but are not resistant to ozone and polar solvents and have only moderate mechanical properties. The performance characteristics depend mainly on the acrylonitrile content and on the degree of polymerization and vulcanization (crosslink density). In general, the higher the nitrile content the greater the chemical resistance but the lower the flexibility. In many cases, a medium nitrile content of 30 to 45 % is the best compromise between flexibility and chemical resistance. A higher crosslink density tends to increase tensile and tear strength, fatigue life but lowers elasticity and elongation at break.1 The performance characteristics of vulcanized rubbers also depend on the type of vulcanizing agent (crosslink structure), filler loading, and amount of additives used.

In general, NBRs have

better temperature resistance than polybutadiene rubbers. Their typical continuous service temperature range is between -25°C and +100°C. Some low acrylonitrile materials are suitable for application down to -50°C and some peroxide cured

grades go up to +150°C.

Because of their excellent oil resistance, NBRs are often used for gasoline hoses, diaphrams, O-rings, gaskets, V-belts and many other (automotive) rubber parts. They are also used for disposable laboratory gloves, foot wear, synthetic leather, printer rollers, and cable jacketing.

Manufacturers & Distributors

Companies |

Brands |