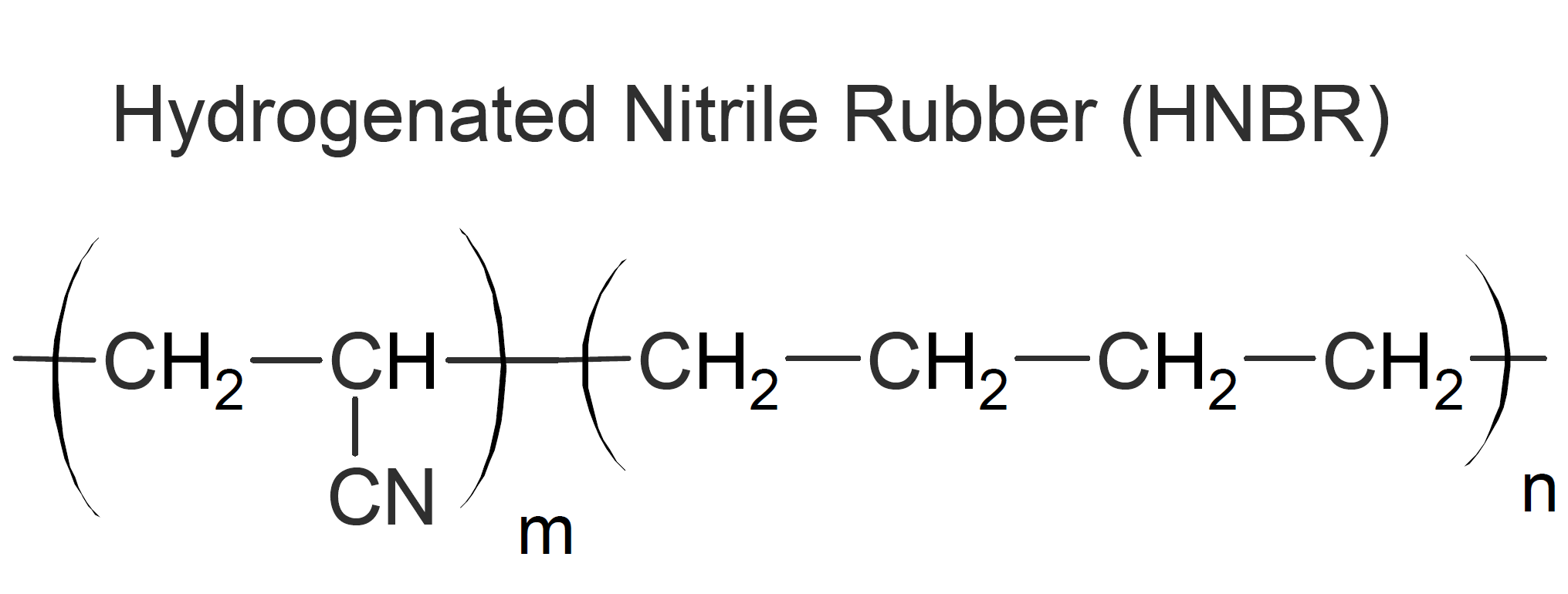

Hydrogenated Nitrile Rubber (HNBR)

Properties and Applications

Hydrogenated acrylonitrile butadiene rubber (HNBR) is a unique elastomer. Its properties depend upon the acrylonitrile content and the degree of hydrogenation of the butadiene part. HNBR has better oil and chemical resistance than ordinary nitrile rubber (NBR) and can also withstand much higher temperatures. The mechanical properties including tensile and tear strength, elongation, and abrasion resistance are also excellent. However, HNBR is more expensive than NBR and has limited resistance to aromatic oils and polar organic solvents. It also has poor flame resistance.

The typical

working temperature range is -25°C to +160°C (-40°F to +320°F). As

with nitrile, many properties can be influenced by varying the

acrylonitrile content in the rubber. High-nitrile HNBR has better

resistance to mineral oils, whereas peroxide/sulfur cured HNBR has the best compression set and heat resistance.

HNBRs are often chosen for applications where resistance to ozone,

weathering, industrial lubricants, amine based corrosion inhibitors

and steam up to 150°C is required. Typical applications include

gaskets and seals, especially for the oil and gas industry as well

as accumulator bladders, and diaphragms.