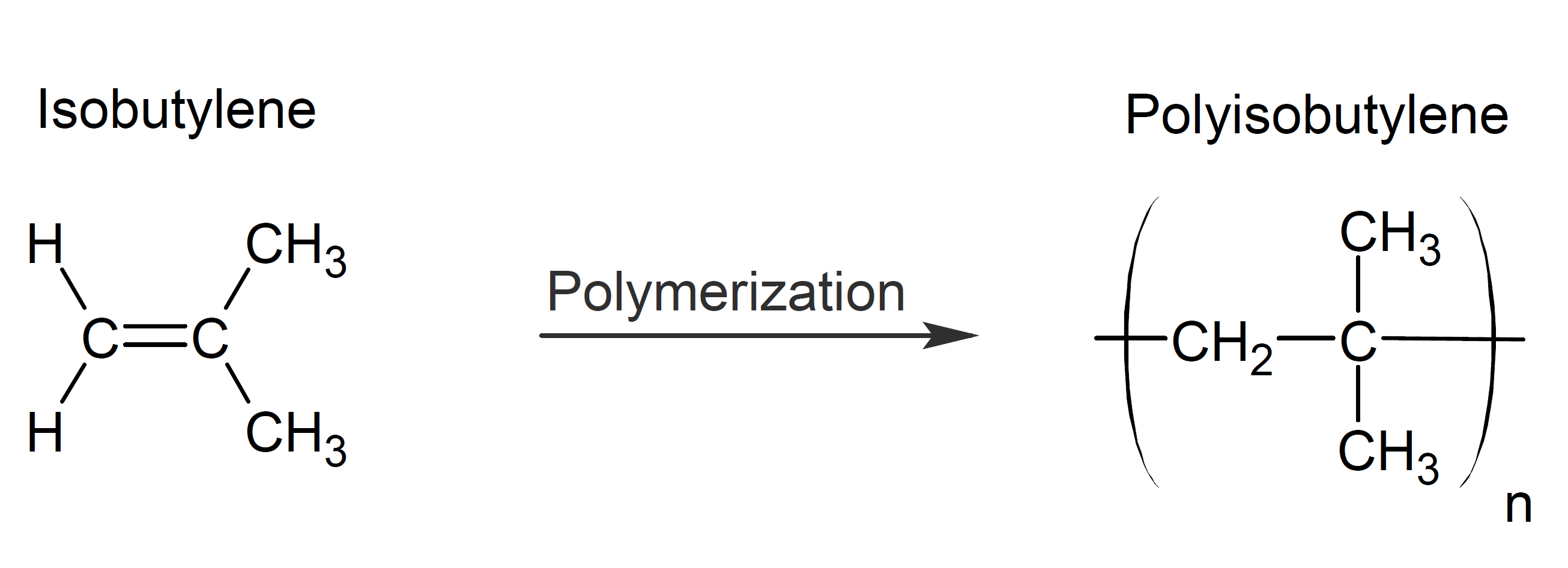

Polyisobutylene

Properties and Applications

Polyisobutylene (PIB) is a low volume commodity thermoplastic. The lower molecular weight grades are colorless to light yellow viscous liquids or sticky solids and the high molecular weight grades are rubbery materials. Isobutylene is often copolymerized with a small amount of isoprene which provides sides for crosslinking (vulcanization). This random copolymer is called butyl rubber (IIR). It is known for its excellent impermeability, good flexibilty and good weathering properties. It also has very good stability against stress cracking, and corrosion and is weldable.

Butyl rubber has unique elastomeric properties that makes it a

good choice for a wide variety of rubber goods. Its low gas

permeability together with its flexibility makes it the ideal

material for inner tubes of tires and other high pressure tubes.

Other applications include diaphragms, gaskets, wire and cable

insulations, liners, O-rings, seals, and weather stripping. Its very low resilience makes it also suitable for shock

absorption, vibration damping and insolation applications.

PIB is

also used in many formulated polymeric products

including adhesives, sealants, chewing gum, roofing membranes, lubricants, cable filling, and synthetic rubber (butyl rubber).

It is often blended with other ingredients such as oils, fillers, and antioxidants, which allows for a versatile variation of the thermophysical and mechanical properties.