IIR – Butyl Rubber

(Isobutylene-isoprene Rubber)

Properties

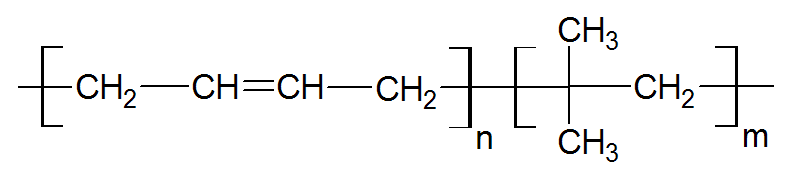

Butyl rubber, also known as Isobutylene-isoprene (IIR), is a synthetic elastomer produced by low temperature cationic copolymerization of 1,1-dimethylethylene (isobutylene) with about 0.5 to 2 percent 1-methyl-1-butenylene (isoprene) using Lewis catalysts in chlorocarbon solvents. The isoprene provides the necessary unsaturation sites for crosslinking (vulcanization).

Butyl elastomers can be vulcanized with sulfur. However, the low level of unsaturation requires more acitve accelerators such as dithocarbamate and thiuram. IIR rubber products can also be vulcanized by quinone dioxime and related compounds.

Butyl rubbers are sometimes blended with other ingredients such as oils, fillers, and antioxidants, which allows for a versatile variation of the thermophysical and mechanical properties.

Butyl rubber (IIR) has outstanding resistance to attack by oxygen and ozone, and good chemical resistance to a large number of organic and inorganic media. Due to the absence of double bonds in the backbone, IIR products can withstand prolonged exposure to heat, and are usually stable in dilute acids and alkalis. IIR has exceptional low gas and moisture permeability which makes it ideal for inner tubes and high pressure/vacuum applications under demanding conditions.

IIR elastomers are sometimes halogenated with chlorine or bromine to improve their resistance to certain chemical media, but at the expense of electrical insulation and moisture resistance. The introduction of halogen also increases the reactivity of the unvulcanized rubber and improves adhesion to other unsaturated rubbers.

COMMERCIAL IIR Products

Important manufacturers and suppliers of IIR rubbers are Lanxess, ExxonMobile, Reliance, and Royal.

Applications

Butyl rubber has unique elastomeric properties that makes it a good choice for a wide variety of rubber goods. Its low gas permeability together with its flexibility makes it the ideal material for inner tubes of tires and other high pressure tubes. Other applications include diaphragms, gaskets, wire and cable insulations, liners, O-rings, seals, weather stripping, and bottle closures. Its very low resilience makes it also suitable for shock absorption, vibration damping and insolation applications. Lower molecular grades find uses in pressure sensitive adhesives, hot melts, caulks, and sealants. Products formulated with butyl rubber have improved chemical and heat resistance.

The typical working temperature range of butyl rubber products is -50°C (-25°C) to +120°C.

In some cases, butyl can be used for the same applications as EPDM elastomers because it has similar resistance to the same fluids as EPDM.