Fluorinated Ethylene Propylene (FEP)

Properties and Applications

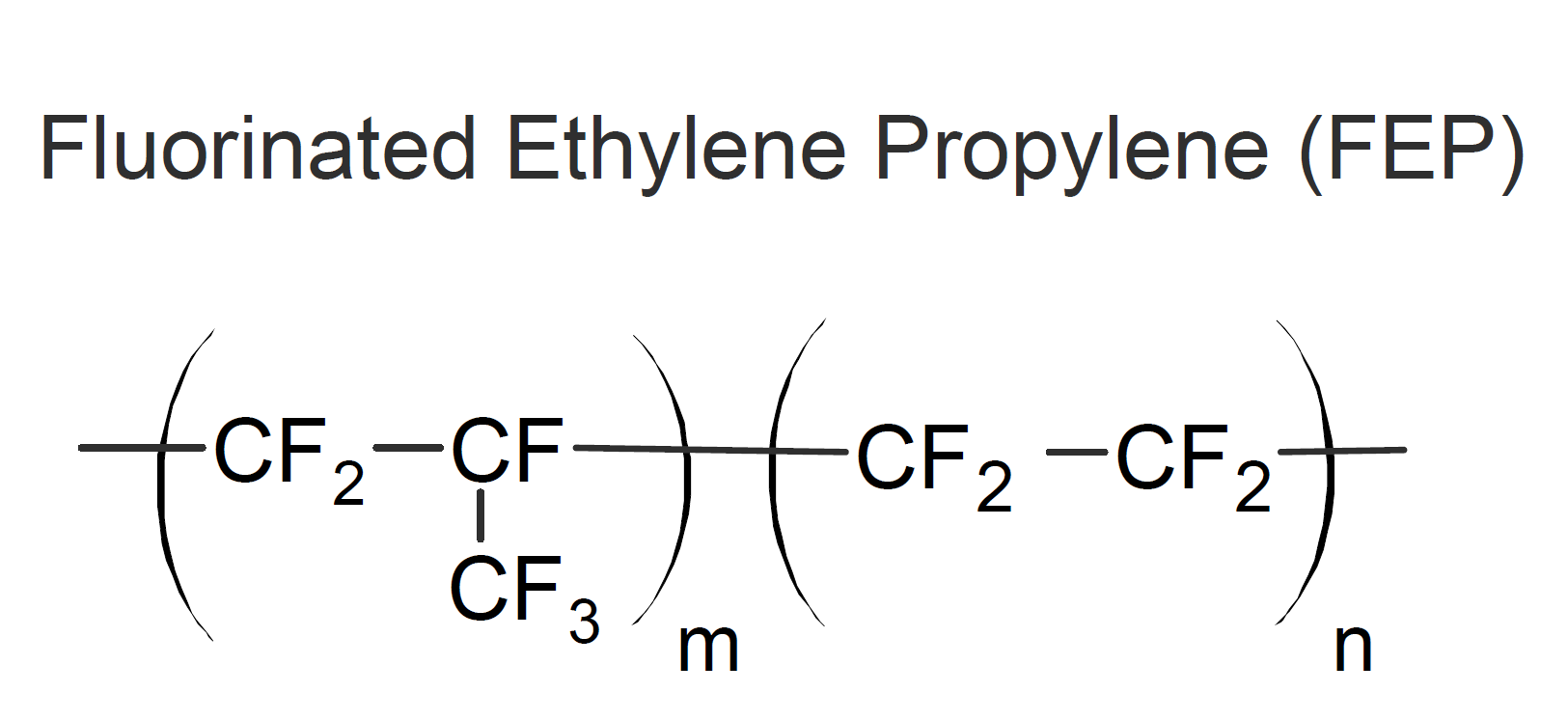

Fluorinated ethylene propylene (FEP) is an inert, transparent and semi-crystalline fluorocopolymer consisting of hexafluoropropylene (TFE) and tetrafluoroethylene (HFP) repeat units. It is prepared by free radical copolymerization of the two monomers in an aqueous dispersion. The introduction of about 5 mol percent HFP in the polymer backbone reduces the crystallinity of FEP copolymers compared with TFE homopolymers resulting in a lower melt viscosity and better processability.1

FEP's thermo-physical properties are very similar to those of polytetrafluoroethylene (PTFE) but slightly inferior. For example, it has outstanding thermal, electrical and chemical resistance, a very low coefficient of friction (self-lubricating and non-stick), and high dielectric strength. However, unlike PTFE resin, it is melt-processable using conventional injection molding and extrusion equipment.

FEP is ideally suited for applications where broad chemical resistance, high durability over a wide service temperature range, excellent dielectric properties and a low coefficient of friction are required or are advantageous. Common applications include thermoformed components, heat-sealable bags, electrical insulation of cables and and connectors, and lining for pipe and chemical processing equipment.

Manufacturers & Distributors

Companies |

Brands |