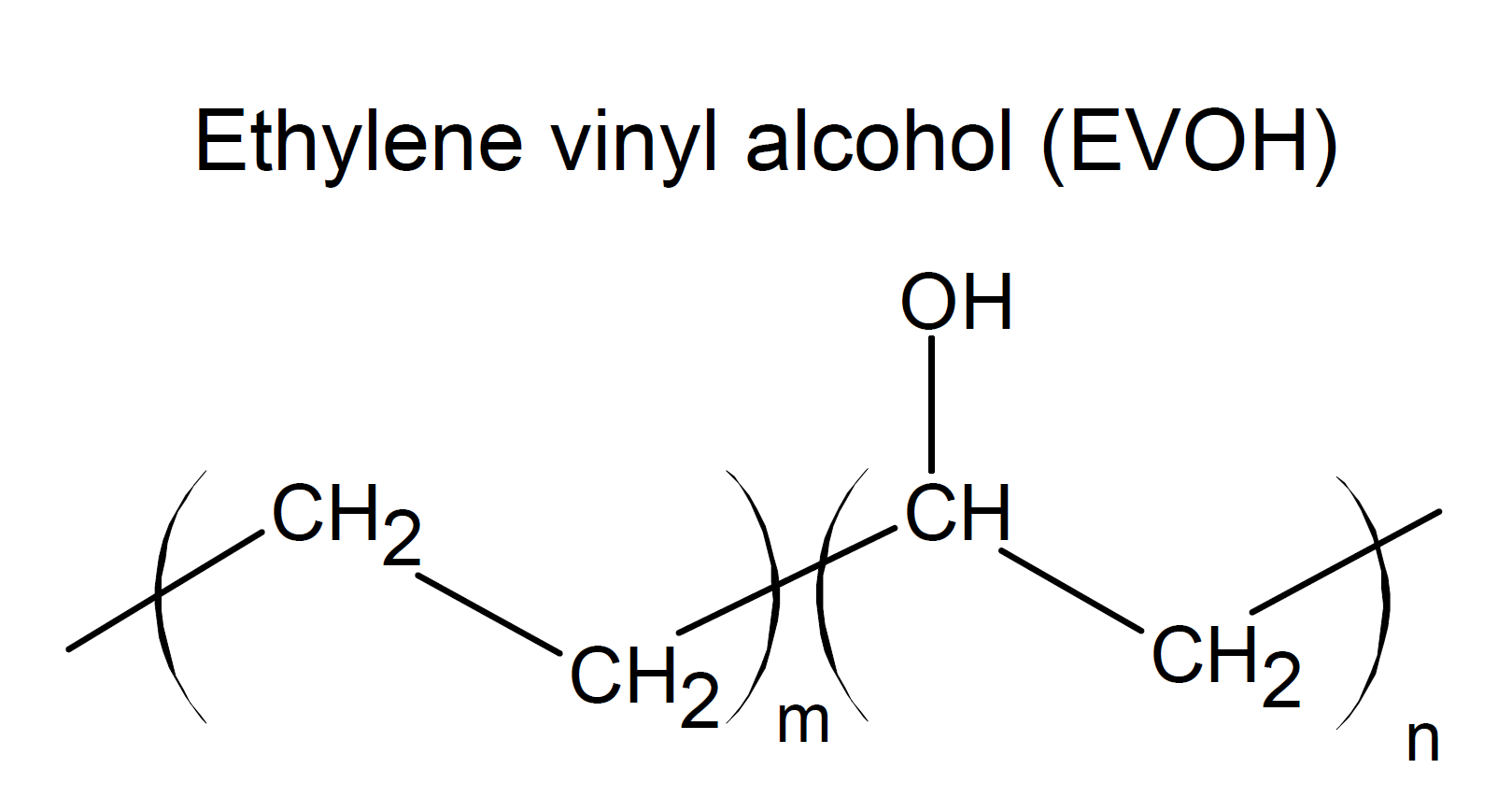

Ethylene Vinyl Alcohol Copolymer (EVOH)

Properties and Applications

Ethylene-vinyl alcohol copolymer or EVOH is a flexible, crystal clear, and glossy thermoplastic copolymer produced through alcoholysis of poly(vinyl acetate). In commercial EVOH resins, the vinyl alcohol content typically various between about 55 and 75 mole percent. Both the melting point and glass transition temperature increases with decreasing ethylene content whereas the oxygen gas transmission rate decreases. In other words, grades with low ethylene content provide the best gas barrier whereas those with the highest ethylene content offer the greatest flexibility and easiest processing.

EVOH possesses excellent flex-crack resistance, very high resistance to hydrocarbons, oils and organic solvents. EVOH has some of the best barrier properties to gases such as oxygen, nitrogen, and carbon dioxide, thus making it especially suited for packaging of food, drugs, cosmetics and other perishable or delicate products to extend shelf life. However, EVOH loses its good gas barrier properties when exposed to moisture. For this reason and to optimize both cost and performance, it is frequently used in multilayer, co-extruded films like HDPE, PP, and PET which have superior moisture barrier properties. Besides packaging, EVOH resins find uses in several other industries such as construction, automotive, cosmetic and agriculture. Important applications include under-floor heating pipes, plastic fuel tanks, agrochemical containers, soil fumigating films, and vacuum insulation panels.

Manufacturers & Distributors

Companies |

Brands |