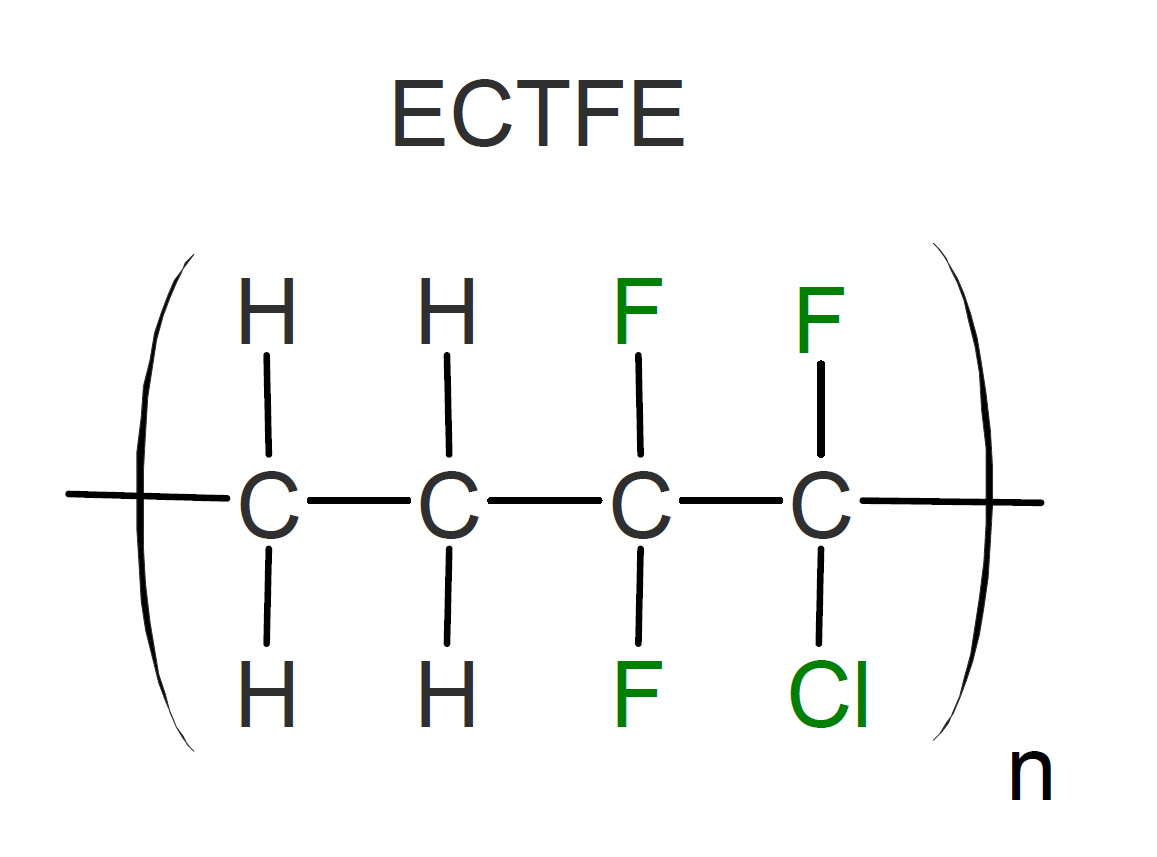

Ethylene Chlorotrifluoroethylene (ECTFE)

Properties and Applications

Poly(ethylene-co-chlorotrifluoroethene), also known as ethylene chlorotrifluoroethylene (ECTFE), is a a semi-crystalline, transparent copolymer of ethylene and chlorotrifluoroethylene. Its properties are very similar to those of ETFE including high impact strength, very good electrical properties, and excellent resistance to chemicals, UV and heat, making it ideally suited for many demanding (load-bearing) applications. However its continuous service temperature is somewhat lower due to the presence of the weaker carbon-chlorine bond. Unlike PTFE, this fluorinated polymer is fully melt-processable by most conventional processing method including extrusion blow, compression, injection, and transfer molding1. It also can be colored and glass or carbon reinforced, allowing ECTFE to be used in a variety of high-performance applications.

ECTFE is often a good choice when low flammability, outstanding long-term weatherability and excellent resistance to harsh environments is required or desired. Its continuous use temperature is in the range from -80 to +150 °C1 making it suitable for continuous use at both very low temperatures and moderately high temperatures. Typical applications include (electrostatic) powder coatings for corrosion protection, (mold-)release films, chemical tank linings, photovoltaic top sheet films, and wire and cable insulations of high-performance cables. ECTFE is also molded into numerous parts such as seals, gaskets, pipes, fittings and pump and valve components which need to withstand abusive environments.