Brominated Epoxy Resins

Properties and Applications

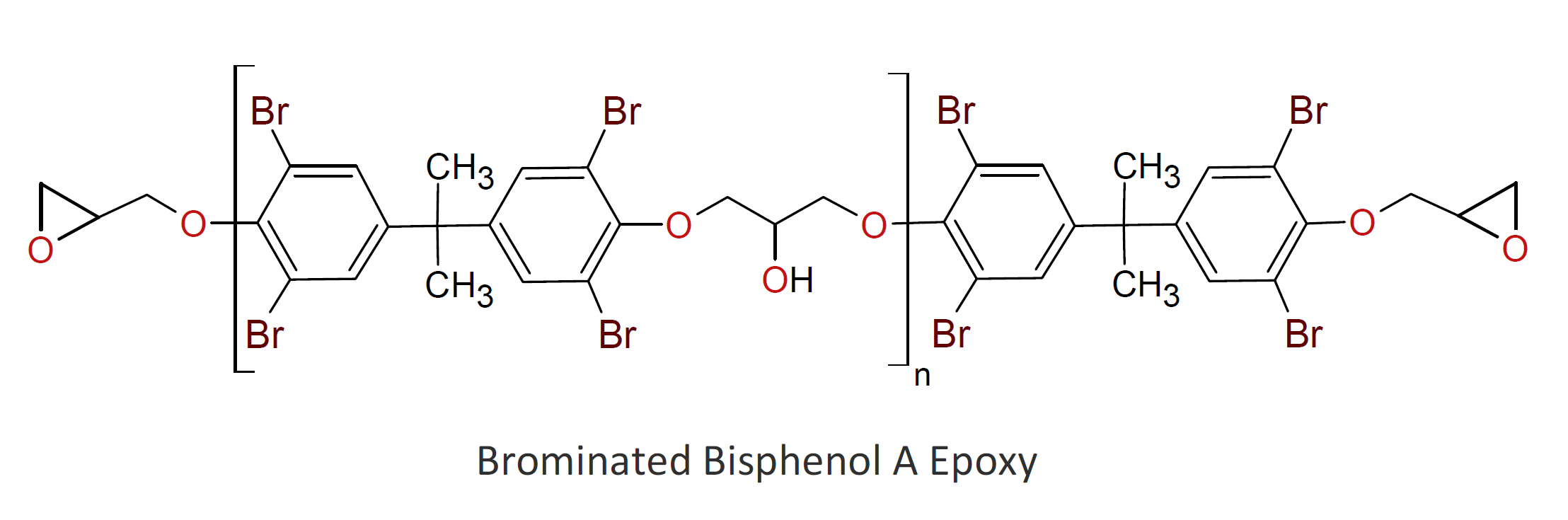

Brominated epoxies (BE or BEO) are specialty thermosetting resins which contain at least one epoxide group. Their properties are very similar to those of regular epoxy resins, but with higher flame resistance due to the bromine constituents in the molecular structure. In addition, they have outstanding electrical properties, high thermal resistance, excellent light stability and typically lower melt viscosities than regular epoxies. On the downside, these resins are more expensive.

Like standard epoxy resins, BEOs can be cross-linked with a wide range of co-reactants including polyfunctional amines, acid anhydrides, phenols, alcohols and thiols. Two very common curatives are dicyandiamide (DICY) and novolac curing agents.

BEOs are typically blended with other resins such as phenolics, unsaturated polyesters, epoxies and a variety thermoplastics to impart improved flame retardancy. Additional benefits may include increased glass transition temperature, toughness, strength, and flexibility.1 Typical applications of BEOs include (powder) coatings, adhesives, composites, paper- or cloth-based laminates (printed circuit boards) and engineering thermoplastic such as PC/ABS, PET, PBT, ABS, Nylon 6/6, and thermoplastic urethanes.