Aromatic Amides (Aramids)

Properties and Applications

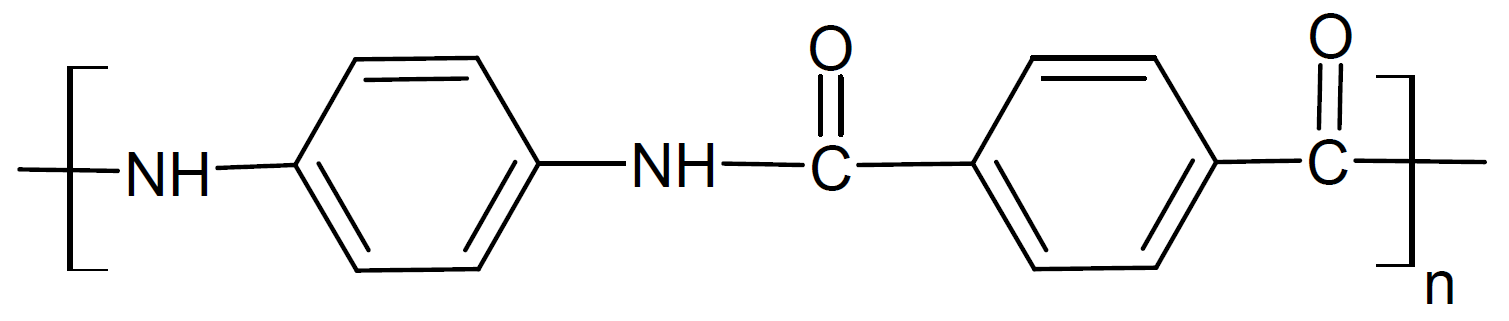

Aramids are wholly aromatic and semi-crystalline high performance engineering thermoplastics. This class of polymers has very high strength, high modulus, and excellent flame and heat resistance as well as greater dimensional stability and solvent resistance than the all aliphatic amides (Nylon). However, aramid resins are much more expensive than aliphatic amides and are more difficult to process. The two most important aromatic amides are poly(p-phenylene terephthalamide), called Kevlar, and poly(m-phenylene isophthalamide), known as Nomex. The chemical structure of Kevlar, the most important aramid, is shown below.

The fully aromatic structure and the strong hydrogon bonds between neighboring aramid chains result in high melting point, high decomposition temperature, ultra high tensile strength at low weight, and excellent flame and heat resistance.

Aromatic polyamides are used for very demanding applications in a variety of industries. Examples include ropes and cables, bulletproof vests, tennis strings, hockey sticks (as a composite), snowboards, jet engine enclosures, brake and transmission friction parts, and gaskets.

Manufacturers & Distributors

Companies |

Brands |