Polyacrylate Elastomers (ACM, AEM)

Properties

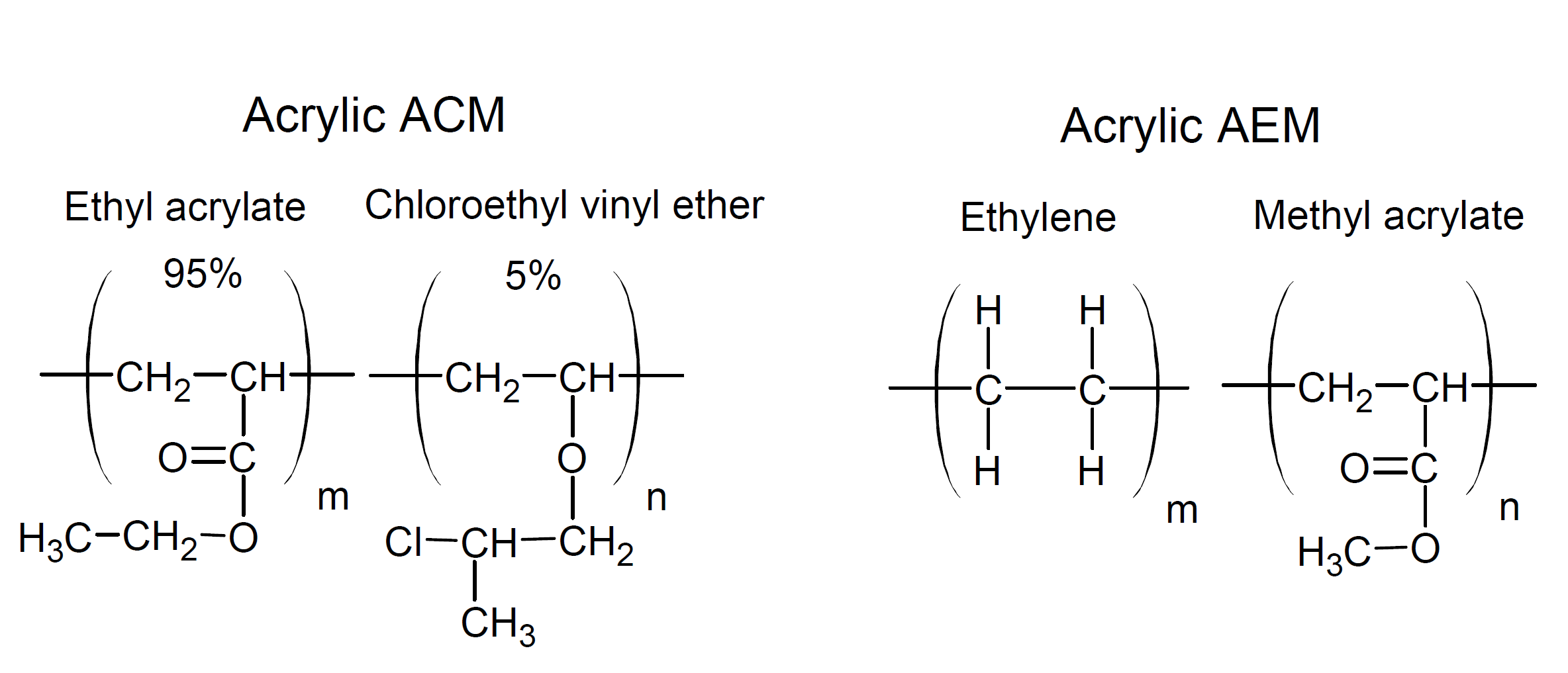

Polyacrylate elastomers, also called alkyl acrylate copolymers, are synthetic rubbers with a glass transition temperature well below room temperature. The two main types of acrylic-based elastomers are polyacrylates (ACM) and ethylene-acrylates (AEM). The later is a terpolymer of acrylate, ethylene and some other monomers whereas ACM elastomers are composed mainly of acrylates such as ethyl acrylate and butyl acrylate. A common comonomer of ACMs is chloroethyl vinyl ether (typically 5%). The basic structure of these types of elastomers is shown below.

Both have similar mechanical properties. However, AEMs can operate in a wider temperature range than ACMs and hydrogenated nitriles (HNBR).

Unlike butadiene-based rubbers (SBS, NBR), acrylic elastomers have good resistance to mineral oils,

transmission fluids, oxygen, ozone, ultraviolet radiation and can withstand higher temperatures.

Applications

Polyacrylate elastomers are widely used in the automotive industry when excellent resistance to transmission and hydraulic fluids and many other common automotive lubricants is required. This includes transmission and power steering seals, O-rings and radiator and fuel hoses. Other applications include diaphragms, plumbing seals, boots, tubes, vibration mounts, pads, isolators and numerous custom molded rubber goods and parts.