EVM – Ethylene Vinyl Acetate Rubber

Properties

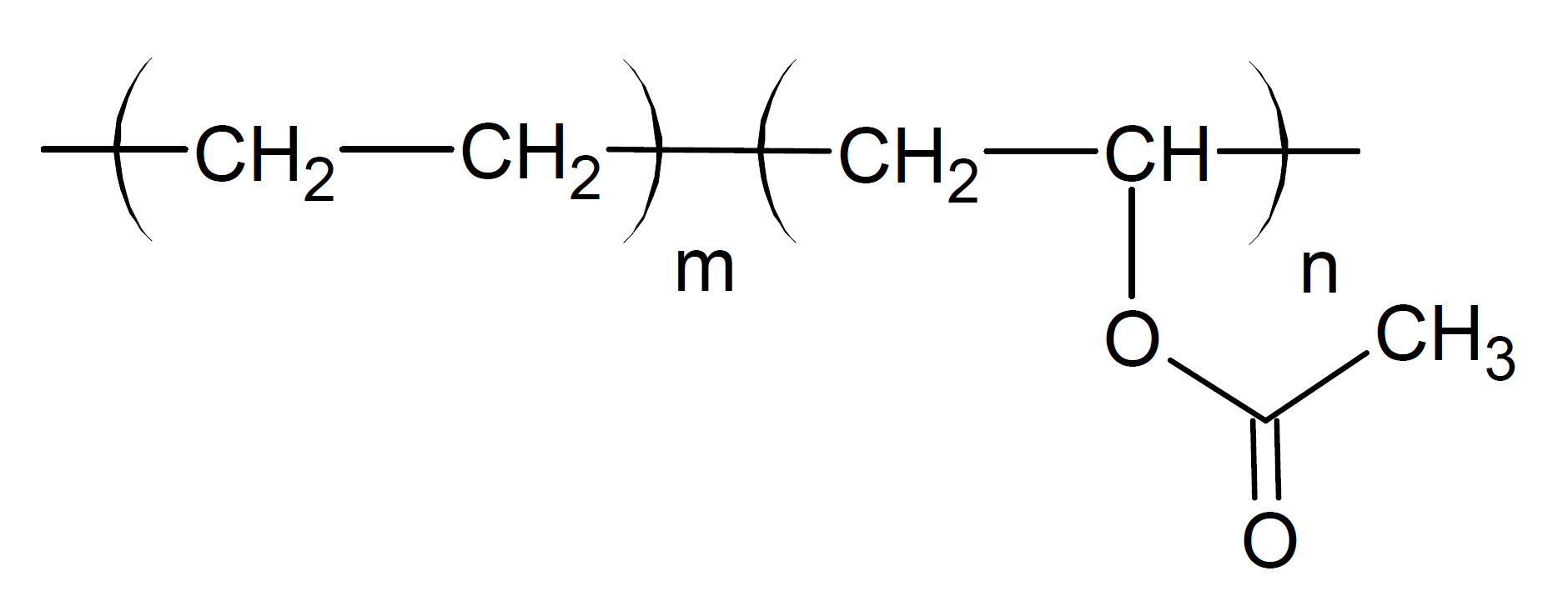

Ethylene vinyl acetate rubber or EVM is a vulcanized copolymer of ethylene and vinyl acetate with a structure as shown below. Crosslinking can be achieved by either reactive extrusion or via radiation using small amounts of peroxide to precrosslink. Its vinyl acetate content typically lies between 40 and 90 percent. Copolymers with high vinyl acetate (VA) content provide high damping at room temperature whereas those with a lower VA content are extremely elastic.

EVM's are special purpose rubbers with very good heat, ozone, and weathering resistance and with little odor. Their oil and chemical resistance depends on the vinyl acetate content; grades with a high VA content have superior oil resistance (less swelling) but are less flexible whereas those with a low VA content are very flexible but show considerable swelling in oil.3

EVM's are a good alternative to many conventional rubbers when superior heat and weathering resistance is needed. In fact, their heat resistance is outperformed only by more expensive silicone rubbers and fluoro rubbers and is equivalent to those of acrylate rubbers (AEM/ACM).

Commercial EVM Elastomers

The major supplier of ethylene vinyl acetate rubbers (EVM) is Arlanxeo,2 which sells a variety of grades with Mooney viscosity ranging from 20 to 60 and with a vinyl acetate contents from 40 to 90 percent.

Applications

EVM is used in several specialty automotive, industrial, and cable applications where superior heat, oil, and weathering resistance is needed. Typical applications include automotive seals such as rocker head covers, flame-retardant and chlorine-free hose covers, flame resistant cable insulation, oil and fuel-resistant rubber hoses, and weather and UV resistant translucent rubber articles.

1The

heat, oil

and chemical resistance depends on the vinyl acetate content. Grades with a high VA content have a superior oil resistance (less swelling).

2ARLANXEO, established in 2016, is a joint venture of LANXESS - a world-leading specialty chemicals company based in Cologne, Germany - and Saudi Aramco - a major global energy and chemicals

company headquartered in Dhahran, Saudi Arabia.

3See Levapren® brochure, reference oil ASTM # 3