Heat Distortion Temperature

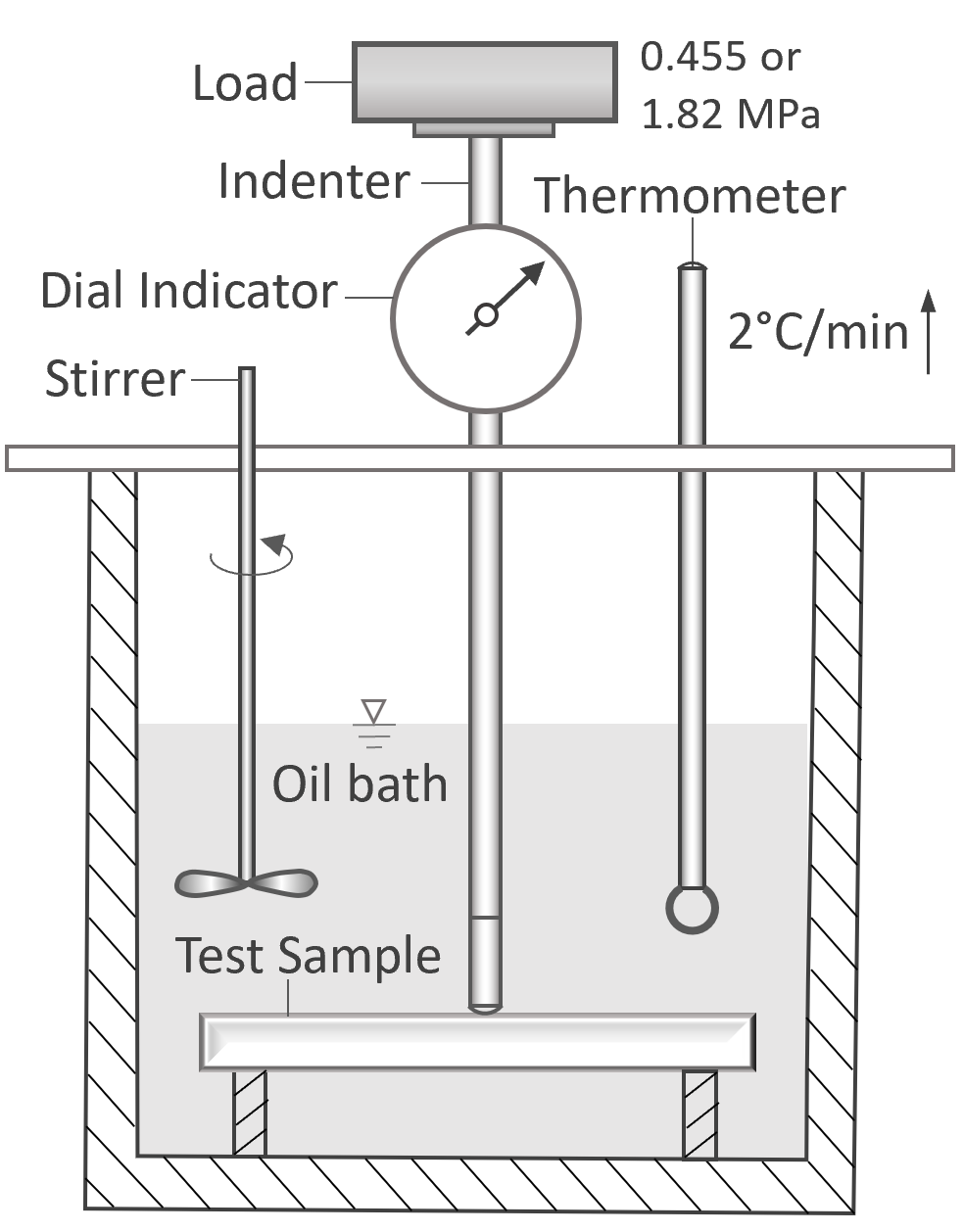

The heat distortion temperature (HDT) - also known as the deflection temperature under load (DTUL) or heat deflection temperature - is an important property of polymers. It gives an indication at what temperature materials start to "soften" when exposed to a fixed load at elevated temperatures. The HDT is defined by ASTM D 648 as the temperarture at which a sample bar of standard dimensions (127x 13 x 12 mm) deflects by 0.25 mm (0.01 in) under a centered standard flexural load of 455 kPa (66 psi) or 1.82 MPa (264 psi). A schematic testing arrangement is shown in the figure below; the sample is loaded to the specified bending stress in a three-point bend test beam arrangement which is immersed in an oil. The oil bath is then heated at a rate of 2 ∓ 0.2 K/min until the specimen reaches the defined deflection.1 The heat-transfer medium is typically a mineral oil or silicone oil which does not affect the mechanical properties of the specimen.

HDT Test

Apparatus

HDT Test Apparatus

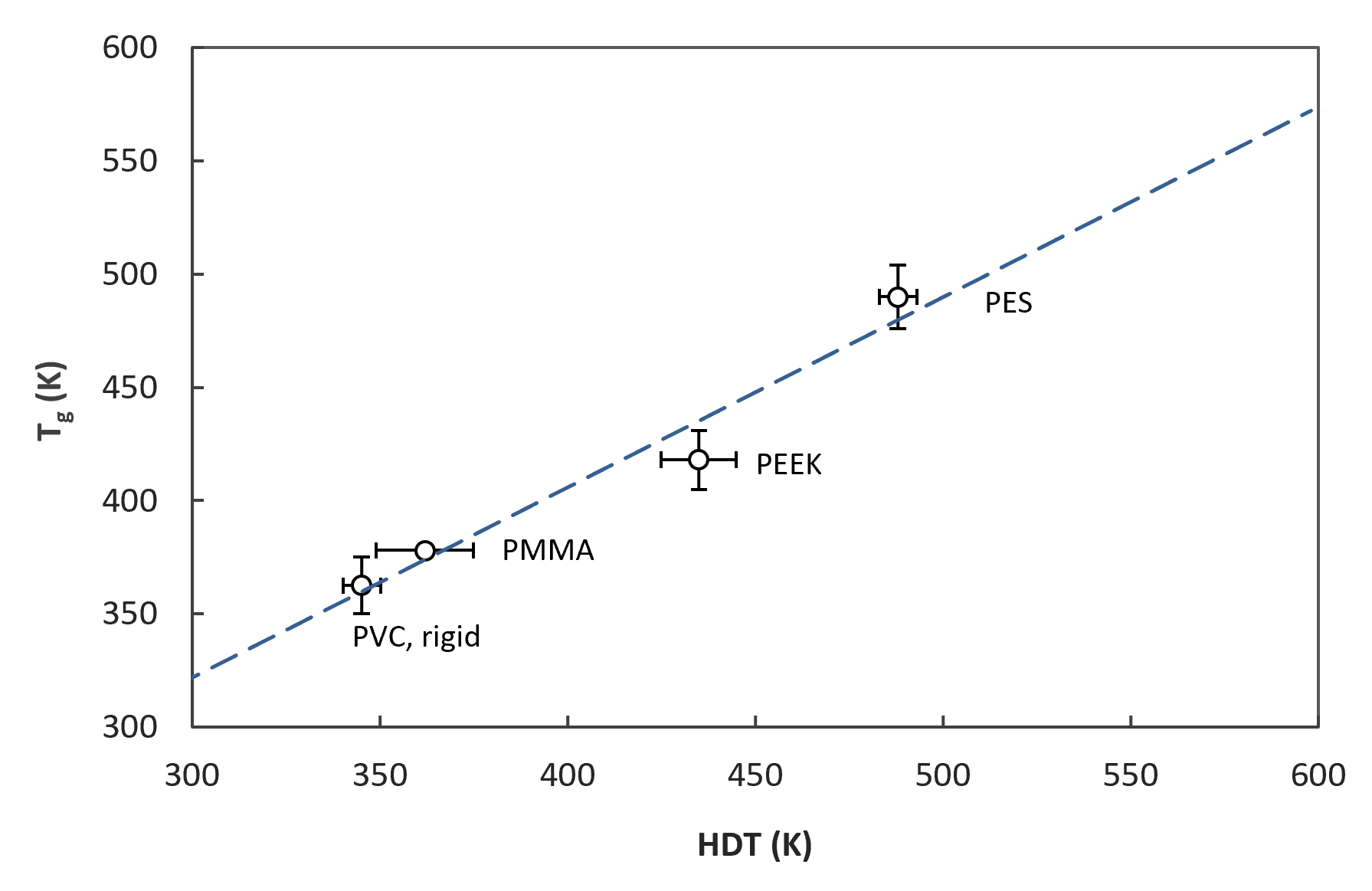

The heat deflection temperature of amorphous materials is related to the glass transition temperature (amorphous materials) or melting temperature (crystalline materials). The HDT, is a useful indicator of the temperature limit above which the material cannot be used for structural applications. It is often reported on the TDS of commercial grades of plastics. However, HDT and Tg (or Tm) cannot be used Interchangeable. The Tg describes the temperature at which vitrification or glassification begins, i.e when "freezing" of the movements of chain segments (kinetic units) takes place, whereas the HDT is a macroscopic measure of the "stiffness" of a material when the temperature increases. For unfilled systems, the two properties are often closely related (see Figure below). However, fillers, and reinforcements will greatly change the HDT since reinforcements make the material stiffer whereas the Tg is not noticeably affected by these ingredients since it describes the softening of the polymeric portion. Infact, the HDT of filled and unfilled plastics can vary a lot, depending on the filler / fiber content and type. Both properties are equally affected by plasticizers.

HDT versus Tg

HDT versus Tg

For structural applications the HDT is often a better measure for the temperature application limit than the Tg (or Tm). Sometimes, manufacturers and suppliers of polymeric materials confuse these two properties. However, these properties are not interchangeable.

1The HDT (ASTM D 648) and the Vicat softening temperature (ASTM D 1525) are often integrated in one instrument (Zwick-Roll).

Revised November 28, 2019