Modified Starch & Starch-based Plastics

Properties

Starch is one of the most abundant biopolymers. It is completely biodegradable, inexpensive, renewable and can be easily chemically modified. Therefore, it is not surprising that starch and its derivatives have received increased attention as biodegradable alternatives to conventional petroleum-based plastics. Maize, potato, tapioca and wheat starch are the most abundant and cheapest starches.

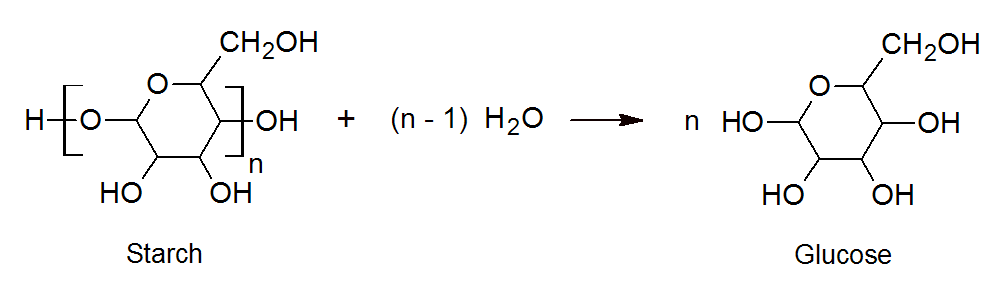

Like cellulose, starch can be considered a condensation polymer because its hydrolysis yields glucose molecules:

The cyclic structure of the starch molecules together with strong hydrogen bonding gives starch a rigid structure and leads to highly ordered crystalline regions. This explains why starch has a high glass transition temperature and melting point and why unmodified starch is only soluble in hot water. The granules first swell and loose their semi-crystalline structure and then burst. The released amylose and amylopectin molecules gradually dissolve and form a network that holds water. This process is known as starch gelatinization and is the reason why during cooking starch becomes a paste of high viscosity.

For industrial applications and for some food application, starch is sometimes chemically modified. This includes esterification, etherification and oxidation. These chemical modifications are accomplished by the addition of suitable reagents to aqueous starch slurries while controlling the pH and the temperature. Sodium sulfate or sodium chloride is often added to restrict swelling of the starch granules. After completion of the reaction, the slurry is neutralized with hydrochloric or sulfuric acid, and then filtrated, washed and dried. The degree of substitution of commercial starch is usually rather low but greatly changes its properties. Depending on the reagents, the reactions lead to nonionic, cationic, anionic or hydrophobic starch which have noticeable different properties. For example, the type and degree of substitution changes the gelatinization temperature and the viscoelastic and mechanical properties of starch. It also affects the stability of the dissolved or dispersed starch granules by controlling or blocking associations of amylose and amylopectin molecules. Certain modifications also improve the freeze–thaw stability which is important for frozen food products.

Starch Esters and Ethers

The two most common starch derivatives are starch acetate prepared by esterification with acetic anhydride and hydroxypropyl starch prepared by etherification with propylene oxide. Esterification is usually carried out at pH 7 - 9 and etherification at pH 11 - 12 and the temperature is usually kept below 60°C. These chemical modifications improve the stability, lower the slurry / solution viscosity and improve the film-forming properties of starch due to increased hydrophobicity.

Dextrin and Thinned Starch

Starch is sometimes partially depolymerized which lowers its solution viscosity. This form of starch is often called thinned starch. Depolymerization may be achieved by an acid or an oxidant treatment, for example by treating a slurry of granular starch with diluted acetic, hydrochloric or sulfuric acid at 40 - 60°C. Dextrins have an even lower molecular weight. They are produced by exposing dry acidified starch to dry heat.

Polyglucose (Polyglucosides)

Alkyl polyglucose (also called alkyl polyglucosides) like lauryl polyglucose are derived from glucose or starch and fatty alcohols. They are often used as all-purpose fully biodegradable nonionic co-surfactants in (sulfate-free) cosmetics, body washes and shampoos.

Cationic Starches

Quaternary ammonium starch is the most common commercial cationic starch. It is prepared by treating starch with 3-chloro-2-hydroxypropyltrimethylammonium chloride or derivatives thereof under alkaline conditions and at ambient or slightly elevated temperature. Cationic starches are extensively used as paper additives, emulsion stabilizers, flocculation agents, thickening agents, and sizing agents. One of the most important applications is the production of paper and cardboard. Cationic starches are known to improve tear strength, help to bind particles together and on the base paper material, and increase the retention of fibers and fillers

Anionic / Oxidized Starch

Commercially important anionic starches include phosphorylated, oxidized and carboxyalkylated starch. The most common form of anionic starch is phosphorylated starch. It is prepared by treating starch with sodium tripolyphosphate. Noteworthy are also carboxymethyl starch, which is prepared by treating starch with sodium mono chloro acetate, and poly(acrylic acid)-starch graft copolymer.

Oxidized or carboxylated starch can be prepared by treating an aqueous or

semi-dry starch slurry/paste with hydrogen peroxide under alkaline

conditions and at ambient or slightly elevated temperature. This

process yields highly carboxylated starch or poly(hydroxycarboxylic acids). Under the right conditions, it is also possible to selectively oxidize hydroxymethyl groups to carboxyl groups

(anionic starch). Oxidated starch has improved biodegradability, i.e. it degrades much faster than conventional starch.

Anionic starches are often used as a rheology modifier, thickening agent, flocculants, emulsion stabilizers,

sizing agents, paper binders and coating agents, particularly for food products.

Starch Plastics (Thermoplastic Starch)

Starch and its blends with aliphatic biopolyesters and cellulose-derivatives are considered the most promising candidates for developing sustainable plastics. Starch is completely biodegradable, abundant, inexpensive and is regenerated from carbon dioxide and water by photosynthesis in plants. However, unmodified starch based plastics have poor physical properties. For example, they are hydrophilic and easily dissolve in water, have rather poor mechanical properties when moist and are brittle when dry. Furthermore, they have a strong tendency to recrystallize and shrink noticeably when drying.

Numerous studies have been conducted to prepare starch based films, composites, and glues with improved properties and for a wide variety of applications including automotive, construction, packaging, marine, electronic and aerospace industries.

The brittleness of starch can be decreased by blending with various natural plasticizers such as glycerol, glycol and sorbitol and by ester- or etherification. Unfortunately, these blends and modifications have poor dimensional and thermal stability and low mechanical strength. The mechanical properties can be greatly improved by grafting multifunctional monomers onto the polymer backbone and by subsequent crosslinking. Typical grafting and crosslinking agents are phosphoryl chloride, acid anhydrides, methacrylates, epoxies, epichlorohydrin, glyoxal, and acrylonitrile among many other compounds. These chemical modifications make starch insoluble in water and improve its stiffness and tensile strength. However, most of these processes are not environmentally friendly. An environmental friendly crosslinking reaction is the esterification of starch with natural occuring or bio-based acids such as citric, succinic or itaconic acid which react with multiple hydroxyl groups at elevated temperature, thus esterification takes place during the drying stage of the mixture (film). The blends usually contains glycerol or other polyols which also react with the diacids, i.e. polyol acts as both a chain extender and plasticizer.

Another approach to overcome the low resilience, high moisture sensitivity and high shrinkage of (thermoplastic) starch is blending with natural and synthetic polyesters such as polylactic acid, polycaprolactone, and polyhydroxybutyrate. To improve the compatibility of the starch/polyester blends suitable compatibilizers such as PVA and starch-g-polymers1 are often added which also improve the mechanical properties. These approaches do not compromise the biodegradability of the starch and many of the compositions are fully compostable. They also have much improved impact resistance and dimensional stability. However, polyester-starch blends are less strong than cross-linked starch.

Granular starch has also been used as a filler to improve the biodegradability of commodity plastics such as polyethylene, polypropylene and polystyrene. To improve the compatibility with polyolefins, the starch granules are usually surface treated or chemically modified to produce hydrophobic starch.

Starch is fully compatible with any strong hydrogen bonding compound such as poly(ethylene-co-vinyl alcohol) and/or poly(vinyl alcohol). These compounds can also function as compatibilizers for polyester-starch blends. Typical blends consist of starch, PVA (or copolymer), glycerol and urea. These compositions are fully biodegradable and have mechanical properties between those of LDPE and HDPE.

Another approach uses copolymers of olefins and polar monomers such (meth)acrylic acid, the later acts as a compatibilizer. Thermoplastic blends of up to 50% starch and poly(ethylene-co-acrylic acid) (EAA) have been prepared. These difunctional reagents are capable of crosslinking starch by reacting with more than one hydroxyl group and, thereby, reinforcing granules.

Often modified and unmodified starch is blended with other biobased polymers to improve its properties and/or to lower its cost. Films made from these plastics are often transparent, flexible, and have good or acceptable physical properties.

The bioplastic market is projected to reach more than USD 30 Billion by 2020.2

COMMERCIAL Bioplastics

Major manufacturers of (starch-based) bioplastics are Futerro, Novamont, Biotec, BioBag, PSI, Huhtamaki, Hitachi and NatureWorks.

APPLICATIONS

Starch and its derivatives are frequently used as additives in food, cosmetics and pharmaceuticals, for example as thickeners, gelling agents and encapsulating agents. In paper making, chemically modified starch is used as an additive to increase dry strength and to bind pigments, and in textile making, it is used as a sizing agent to reduce wear and warp during weaving.

Starch based adhesives are frequently used to bond binders, wall paper, envelopes, corrugated cardboard, bags, labels, laminates, cigarette tips and side-seams. Various starch derivatives are sometimes added to drilling fluids to control fluid loss in drilling operations.

Bioplastic are mainly used for packaging such as cups, bowls, bottles, cutlery, egg cartons, and straws. Other applications include disposable bags and trash liners as well as compostable films for agriculture.

1Graft copolymerization is often used to modify the properties of starch. The polyesters are chemically bonded onto the starch. These graft-copolymers can be used directly as thermoplastics or as compatibilizers for other starch based plastics

2K. Laird, Plastics Today, Packaging Materials, Nov. 23, 2015