Autoacceleration; Trommsdorff or Gel Effect

In free-radical

polymerizations, an autoacceleration of polymerization rate is

typically observed when the monomer concentrations is high and when

the conversion reaches a certain value. For free-radical polymerization one expects a first-order kinetic with

respect to the monomer concentration. This is indeed observed for most vinyl polymers over a wide extent of polymerization. However, the polymerization of some monomers, both undiluted and

diluted,

shows a marked deviation from first-order kinetics at a certain

conversion. One observes a considerable increase in both the

polymerization rate and the molecular weight which is known as the

Trommsdorff or Norish-Smith effect in recognition

of their contributions in this field. The effect is particularly pronounced with methyl

methacrylate, methyl acrylate, and acrylic acid at various

concentrations. It occurs also with other monomers, such as styrenes

and vinyl acetate, but for these monomers the effect is less

pronounced.

Autoacceleration is independent of the initiator and

can be observed even under isothermal conditions. In fact, if the

reaction is exotherm, autoacceleration results in in a noticeable

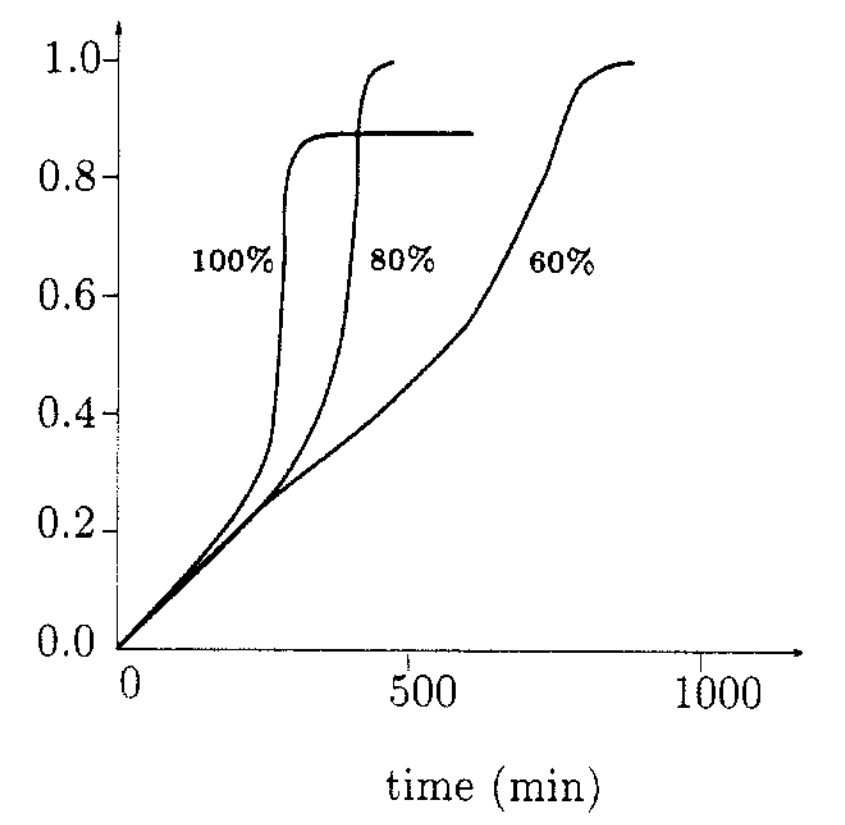

increase in temperature. An example is shown below for the

polymerization of methyl methacrylate at 50 °C in the presence of

benzoyl peroxide initiator (BPO) at various initial concentrations of

monomer in benzene.3

Polymerization of PMMA at 50 °C in the presence of BPO at various Concentrations of Monomer in Benzene

According to the kinetics of free radical polymerization, the rate of polymerization depends on the rate constants of initiation, propagation and termination:

Rp ∝ kp (f kd / kt)1/2

Since the effect is not a function of the initiator, it must depend on the

rate constant ratio kp/kt1/2, which has to increase by as much as a hundredfold to explain the effect shown in the figure above.

Norrish and Smith1, Trommsdorff2, and Schulz and Harborth3

postulated that the drastic increase in the rate of polymerization

and the simultaneous increase in the average molecular weight is

caused by a noticeable decrease in the termination rate when the system reaches a certain concentration and molecular weight. They attributed the decrease in the termination rate

kt

to the high viscosity of the medium at high(er) conversion rates

(around 20 %).

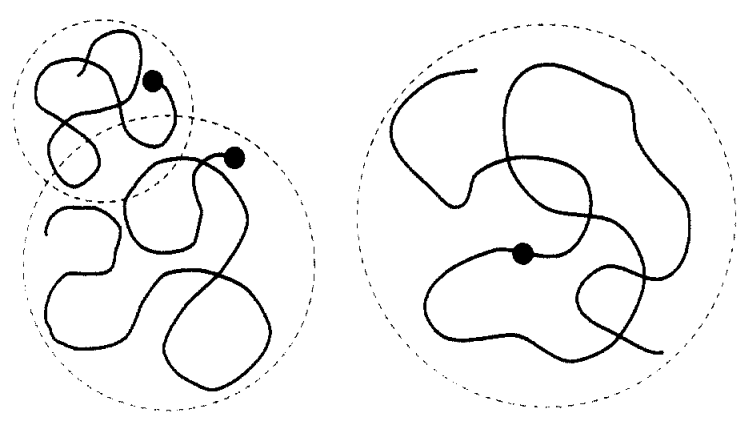

According to Trommsdorff et al., the overall diffusion rate of the

growing polymer chains depends on the viscosity of the medium. If

the viscosity is high, the termination rate, that is, the combination of

two free chain radicals, becomes diffusion controlled.

Although the intrinsic reactivity of the free radicals does not change much, the probability that two radicals will approach and annihilate each other will be rather small since the kinetics of the termination will be dominated by entanglement and (chain-end) diffusion. In fact, the reaction rate between two polymers of very different length will be entirely determined by the shorter chain and the rate of termination is given by a power law5:

kt ∼N-α φ-β

where φ is the volume fraction of polymer and N is the average chain length.

The consequence on termination reactions is dramatic; since

N is large, the net rate of termination in the autoacceleration

regime will dramatically decrease, whereas the reactivity of the

monomers will not change much due to the small size of the monomers.

In fact, the concentration of active radicals will rise to a much higher level, and consequently, the

consumption of monomer will increase proportionately.

Another important consequence is, that the addition of a polymer,

like a rubber toughener, will shift the Trommsdorff effect to lower

polymer concentrations, φ.

O'Shaughnessy and Yu5 found that both the slope of conversion and width of

the autoaccleration region are independent of initiator species and concentration.

References

- R. Norrish and R. Smith, Nature 150, 336 (1951)

- E. Trommsdorff, H Koehle, and P Lagally, Makromol. Chem. 1, 169 (1948)

- G.V. Schulz and G. Harborth, Macromol. Chem. 1, 106 (1947)

- P. J. Flory, Principles of Polymer Chemistry, New York 1953

- B. O'Shaughnessy, J. Yu, Macromolecules 27, 5067 (1994)