Polysilanes

Properties and Applications

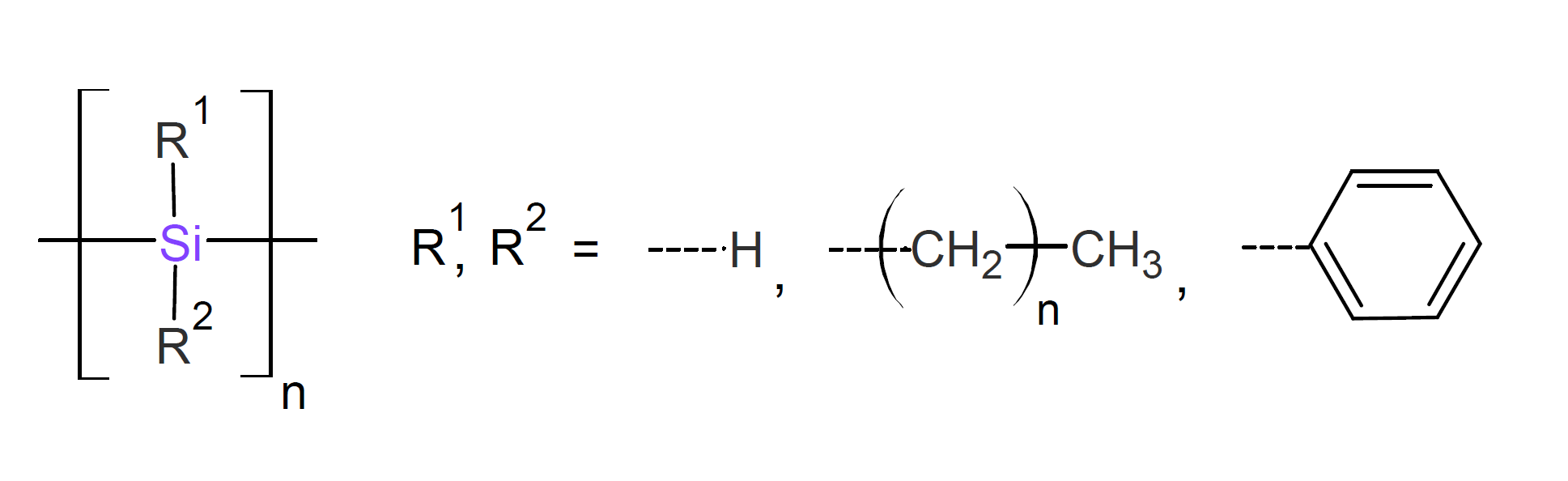

Polysilanes are a class of heat stable inorganic polymers with a polymer backbone made up entirely of silicon-silcon bonds with two substituents attached to each silicon atom including hydrogen, alkyl, and/or aryl groups. A large number of different polymers belong to this class which cover a wide range of properties from highly crystalline and rigid to fully amorphous and very flexible solids. Most of these polymers have excellent heat resistance and are not very susceptible to hydrolysis but photodegrade when exposed to ultraviolet light.

Polysilanes are mainly used as precursors for silicon carbide whereas the silane based polymers itself have found only a few commercial applications. The most important (potential) application appears to be in the microlithography for electronic devices. When used as photoresists, they undergo scission when exposed to ultraviolet light.

Organofunctional silane monomers are sometimes incorporated into adhesives and sealants. They are either chemically bonded to the base polymer (STP-E = silane terminated polyethers, STP-U = silane-terminated polyurethanes), or they are added to formulated products for various purposes. For example, they function as crosslinkers in moisture curing adhesives and sealants or as adhesion promotors for a variety of substrates. They also improve the physical and mechanical properties of filler-reinforced products.