Polyanhydride Resins

(Styrene-Maleic Anhydride and other Resins)

Properties

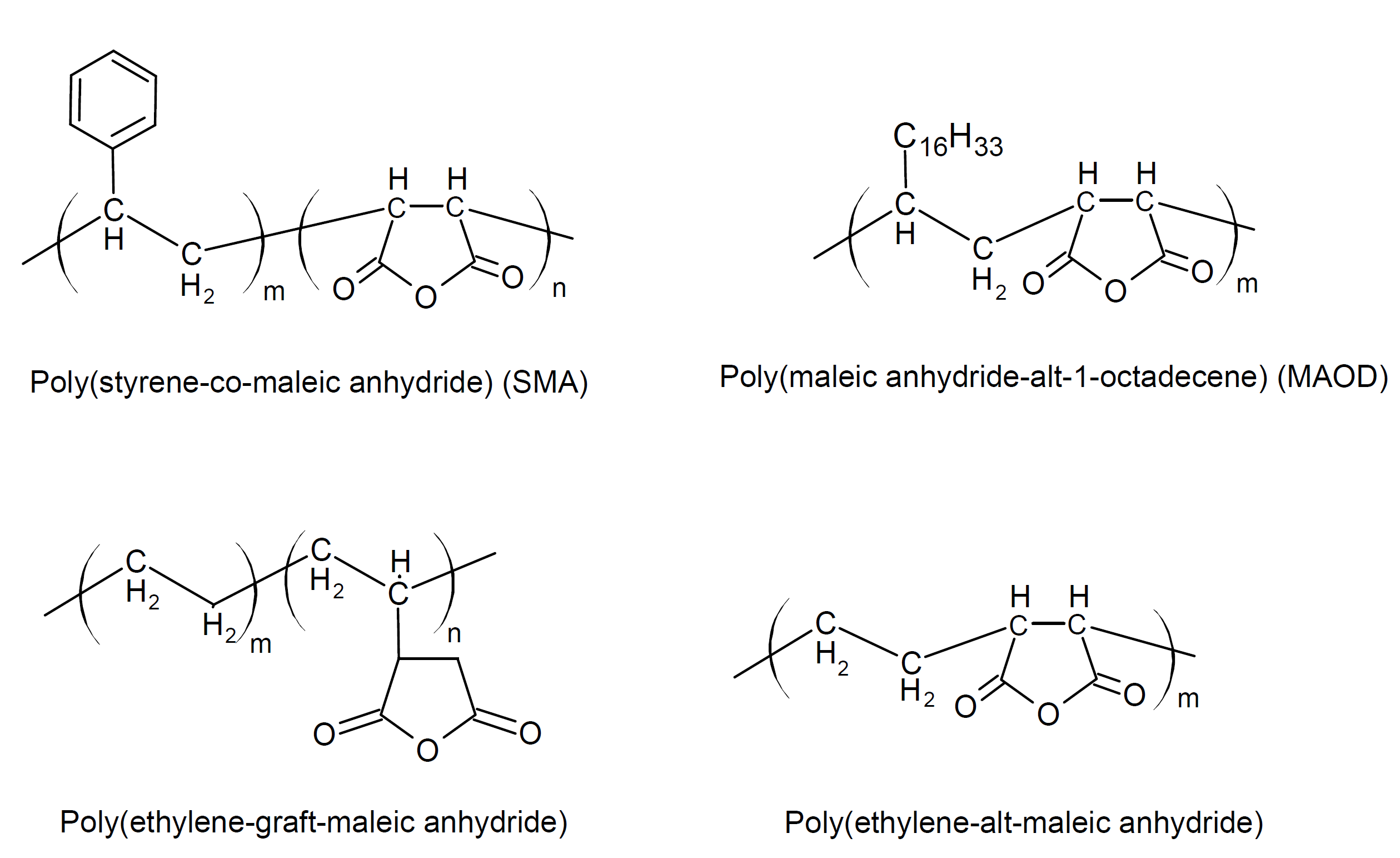

Maleic anhydride copolymers (MAC) are specialty resins derived from copolymerization of maleic anhydride and a vinyl monomer. The most common anhydride resin is poly(styrene-co-maleic-anhydride) (SMA). It is a crystal clear, amorphous thermoplastic formed by free-radical copolymerization of styrene and maleic anhydride. SMA offers high heat and chemical resistance, high gloss, and high melt viscosity. Some impact-modified SMA grades are also produced which have excellent impact resistance. Other commercially available MAC resins include poly(1-octadecene-alt-maleic anhydride) (MAOD), and poly(ethylene-alt-maleic anhydride), as well as MA grafted copolymers such as poly(ethylene-graft-maleic anhydride) and SEBS block copolymers with maleic anhydride grafted onto the rubber midblock.

Maleic anhydride resins are well known for their high functionality and reactivity. For

example, the anhydride portion of SMA can act as a hardener for

(heat-curable) epoxy

formulations (powder coatings). The anhydride groups in MAC resins are noticeably less reactive towards atmospheric moisture up-take and hydrolysis than most non-polymeric anhydrides.

SMA resins are sometimes partially esterified. These resins contain a combination of anhydride, mono-ester and carboxylic acid functionality. SMA ester resins possess low melt viscosities as opposed to SMA base resins, high reactivity typical of carboxylic acid functionality, improved solubility in many polar organic solvents as well as good compatibility with many polymeric and nonpolymeric surfactants.

Applications

As a molded plastic, SMA copolymers / resin blends find uses in the automobile industry for instrument panel and console

applications. The SMA surface provides excellent adhesion to polyurethane foam (PUR) used for padded instrument panels.

SMA is an excellent compatibilizer for many resin blends that are normally immiscible.

It contributes to stiffness, thermal stability, and chemical

reactivity and makes molded parts easier to bond and paint at much lower cost.

SMA (ester) resins are also added to many formulated products such as

adhesives, solvent-based coatings, overprint varnishes, printing inks,

powder coatings as well as carpet/textile cleaners and floor care products.

They function as polymeric dispersing and emulsifying agents, and as high functionality crosslinkers.

Copolymers of other vinly monomers and MA are produced on a smaller

scale. They are used as viscosity modifiers for solutions,

suspensions and emulsions,

as dispersing aids for insoluble solids, as chelants and surfactants and as

high-functional epoxy curing agents. A commercially important MA

vinyl resin is poly(maleic anhydride-alt-1-octadecene).

Manufacturers & Distributors

Companies |

Brands

|