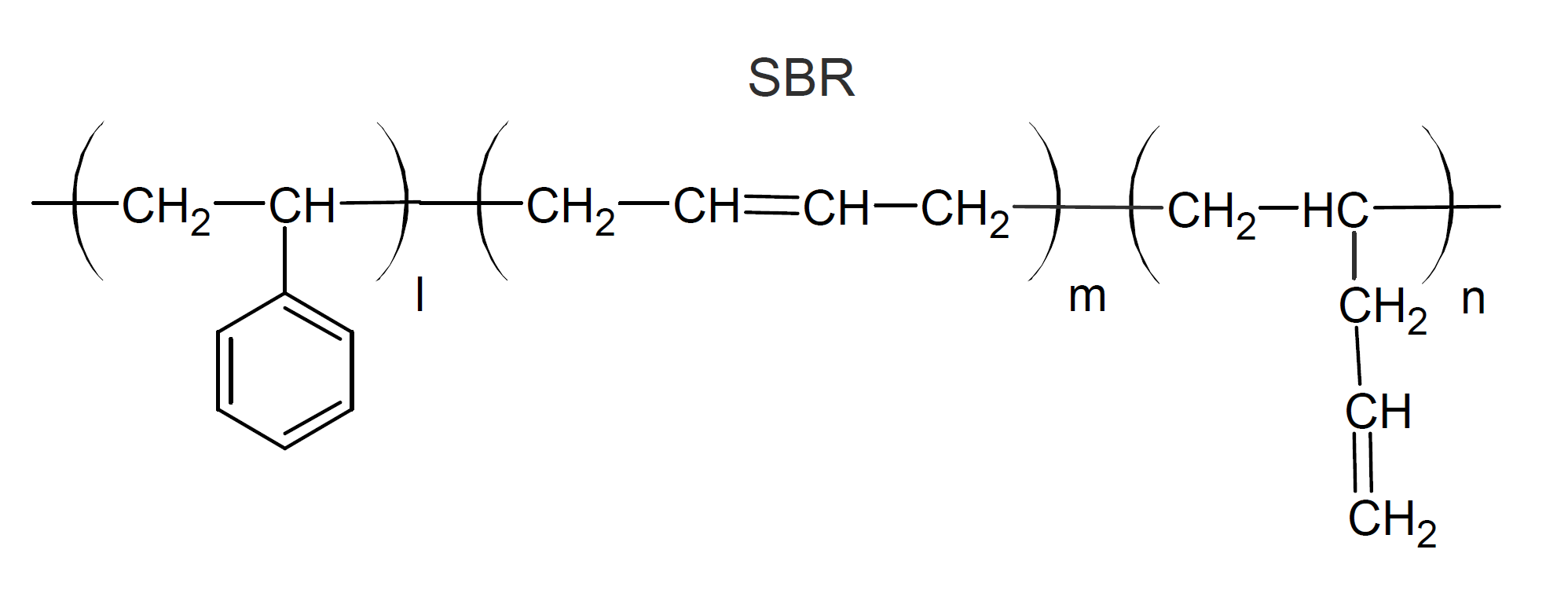

Styrene-Butadiene Rubber (SBR)

Properties and Applications

Styrene-butadiene rubber (SBR) is the largest-volume elastomer. It is a highly random copolymer of butadiene and 10 to 25 percent styrene. The addition of styrene increases the strength and contributes to the good wear and bonding properties. It also reduces the price of the rubber and often improves the compatibiltiy with other materials in blends. SBRs are known for their excellent abrasion resistance but have poor ozone and mineral oil resistance. Many grades of SBRs can withstand temperatures between -40°C and +100°C (-40°F and +210°F) for prolonged periods of time. However, their low temperature flexibility and tensile strength are less than that of natural rubber.

Typical applications include drive couplings, haul-off pads, conveyor belts, shoe soles and heels, adhesives, roll coverings and car tires (but not truck tires) and various other molded rubber goods. The typical working temperature range is -25°C to +100°C (-12°F to +212°F) for static sealing applications.

Manufacturers & Distributors

Companies |

Brands |