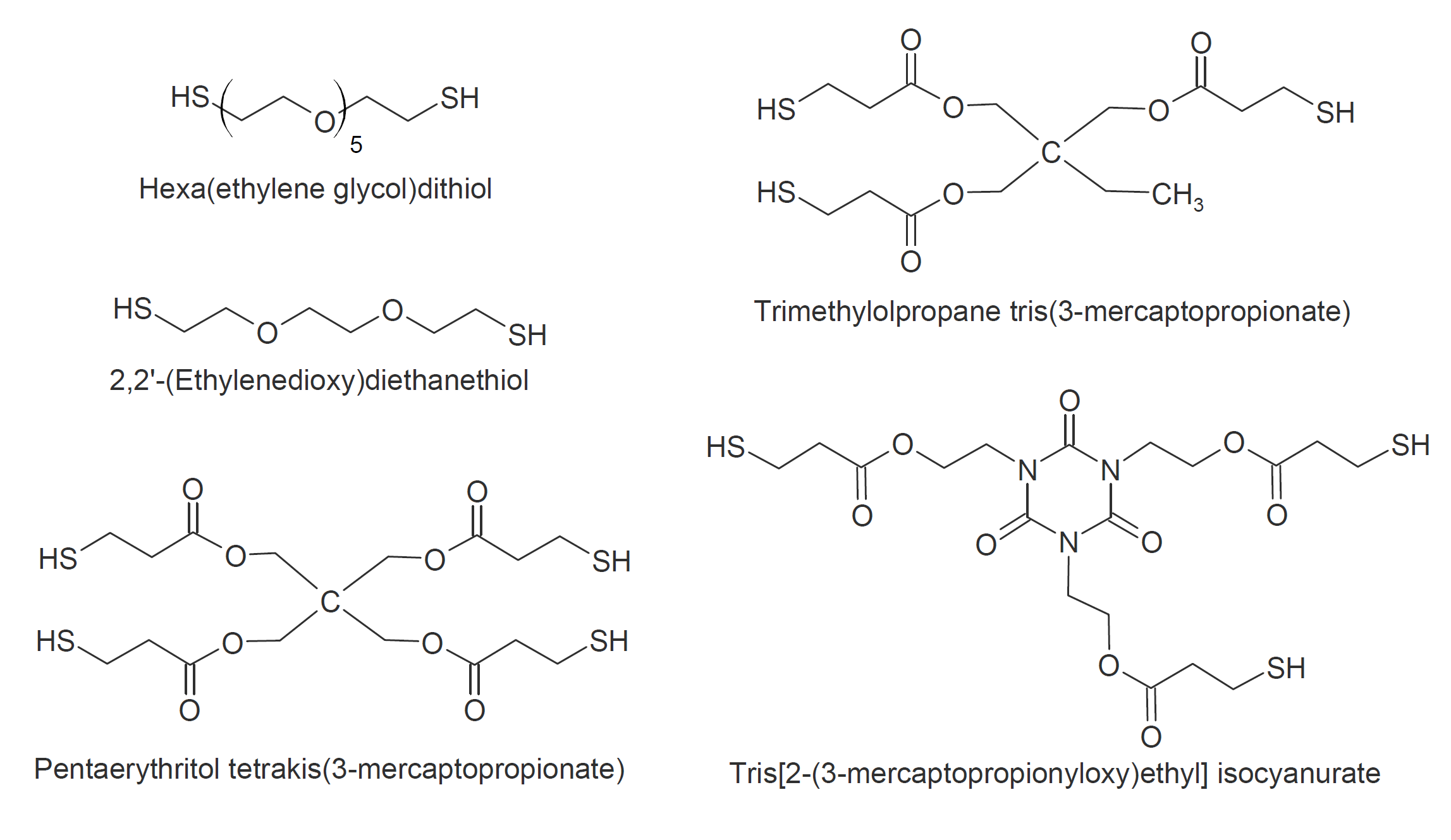

Polythiol Curing Agents (Polymercaptans)

Properties and Applications

Polythiol curing agents, also known as polymercaptans or multifunctional mercaptans, are compounds with at least two metcaptan functionalities. They are typically colorless, have low viscosity, and are highly reactive when used as liquid curing agents.1

These resins can be cured to thermoplastics or thermosets when reacted with various base resins including epoxies, isocyanates, unsaturated hydrocarbons and vinyl esters. When cured with epoxy resins, they provide good mechanical properties, little to no discoloration, and good to medium resistance to many chemicals whereas the water and solvent resistance depends on the system and application. The oligomeric polyether/polyester mercaptans also increase the flexibility and toughness of the cured resin systems. Two major disadvantages of mercaptans are strong (pungent) odor and significant exothermal heat generation in fast curing epoxies and isocyanate formulations. In thermal or UV initiated radical addition, polythiols exhibit high reaction rates with double bonds, lower shrinkage and, unlike acrylates, no oxygen inhibition.

Polythiol are mainly used as curatives for other resins. They are used in several formulated products including adhesives, floor and decorative coatings, optical lenses, coatings of electronic circuit boards, and B&C sealants (polysulfides). For example, they are used as hardeners in „5 minute“ epoxy glues, and as reactive thinners or binders for isocyanate coatings and adhesives. Many of these products can be formulated to water-clear products since the reaction of thiols with acrylates and epoxies does not cause any significant discoloration. Polythiols also function as chain transfer agents in free radical polymerization and as corrosion inhibitors.

Manufacturers |