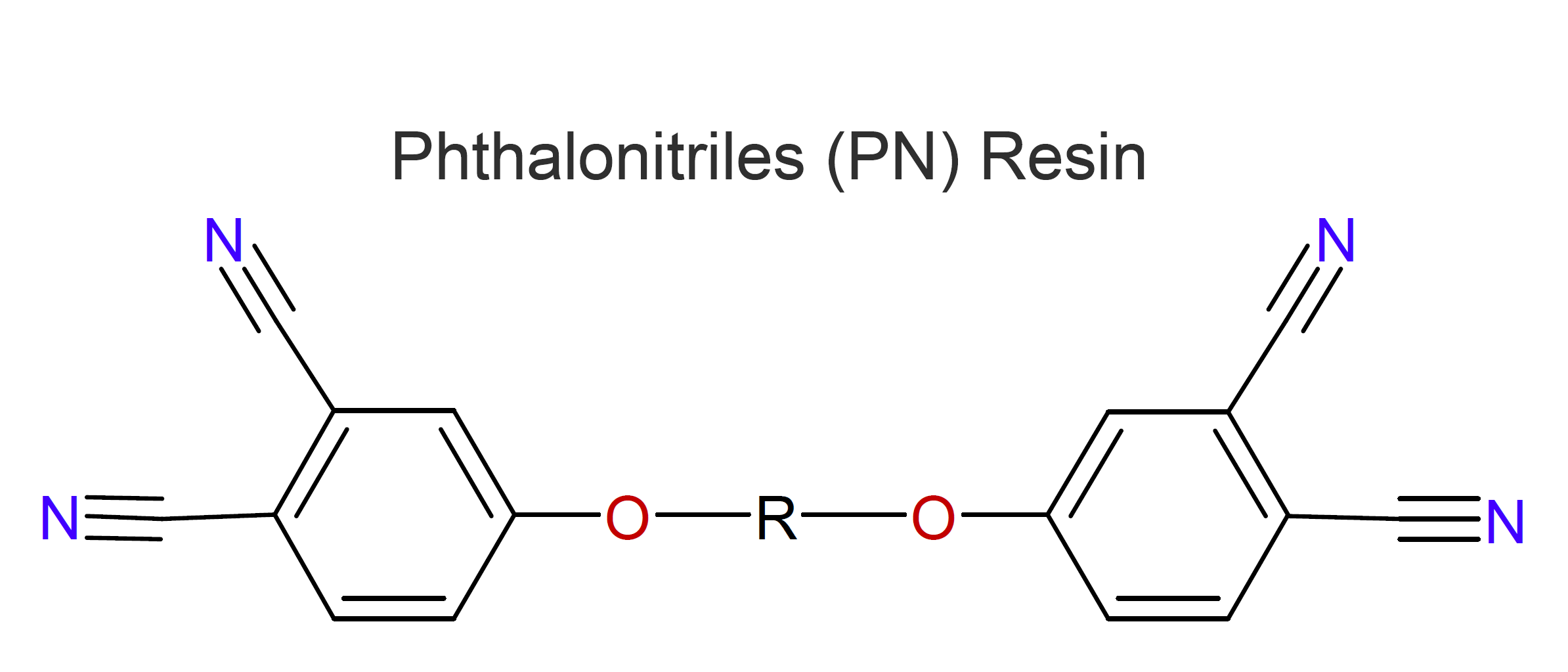

phthalonitriles (PN)

Properties and Applications

Phthalonitriles (PN) are a relative new class of commercial high performance engineering thermosets.1 The resins can be prepared by nitro-displacement of nitro-phthalonitriles with phenoxyphenols in the presence of a base. The resulting resins are typically cured with amine curing agents such as 1,3-bis(3-aminophenoxy)-benzene (m-APB) at temperatures between 200 and 300 °C which leads to the formation of triazine and phthalocyanine structures.

PN cross-linked polymers exhibit very high thermal and oxidative stability, and high temperature properties. Infact, PNs have one of the highest decomposition temperature of all organic thermoset polymers which can approach 500 °C (930 °F) in air.2,3 They also exhibit no Tg before decomposition. Other important benefits include very low water absorption, outstanding structural integrity when exposed tho excessive heat or fire. However, PNs have some major limitations and shortcomings. For example, they are very expensive and difficult to process. Recently, a new class of PN resins has been developed, the so-called second generation PEEK-like phthalonitriles which allow for more cost-effective manufacturing due to a simpler two-step and one-pot cure and cheaper starting materials. For example, composites can be produced by well established industrial methods such as resin transfer molding (RTM) and resin infusion molding (RIM), and by other low-cost manufacturing techniques.

PNs are often an excellent choice for very demanding applications where very high mechanical strength in combination with high temperature resistance are required. They can replace polyimides for demanding aircraft applications and vinyl esters and epoxy resins in structural composites in the transportation industry due to their good processability and superior physical properties. Other (potential) products include high temperature adhesives and coatings, fire-resistant garments and building materials, as well as valves, seals, bushings, bearings, wind blade components and other structural parts that have to survive in harsh and hot environments. PNs can replace metals, ceramics and other high performance materials in many applications.